Automatic Inspection System Aoi Machine Vision For Rubber Sealing Ring

|

|

Product background Cars are the most important means of transportation in modern

people's life. The birth of cars can expand the radius of people's

life and expand the radius of people's work choices. This has

positive significance for social and economic advancement.

Automobile is an important product in the stage of industrial

development, and it is also an important symbol of the level of

industrial development. Because cars are made up of tens of

thousands of parts, dozens of industries are involved. Each

component is a reflection of the development level of the industry.

The material of the automobile oil seal is basically a rubber

injection material with a certain hardness, which may cause defects

in the production process. Therefore, in order to occupy the market

in the auto parts industry, sealing ring manufacturers have

upgraded from the original manual quality inspection to machine

vision robot inspection.

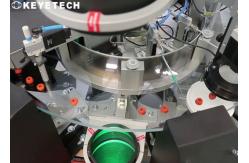

Inspection principle The materials are arranged by vibrating plate, Linear vibration and non-destructive conveying, and the capacitance is stably and orderly transferred to the specific inspection station, and then the high-pixel sample image captured by the industrial camera is transferred to the image processing software. After the system analyzes and processes, it judges good and defective products, and controls the corresponding pneumatic components to eliminate the defective products, and finally collects qualified products. The traditional manual inspection method has been difficult to meet the inspection needs of the production process of automobile oil seals. To ensure high-quality products, modern testing equipment is inseparable. The introduction of automated visual testing equipment is an essential choice in the production of automotive oil seals. Quality control is now the core competitiveness among manufacturers in the manufacturing supply chain.

Inspection details&machine configurations The inspection machine adopts high-pixel industrial cameras and high-performance stroboscopic light sources to carry out omni-directional visual inspections for product appearance defects. The equipment can realize 7*24 hours of all-weather operation, and it can be online automatically. Eliminate substandard products.

Our advantages

|

|||||||||||||||||||||||||||

| Product Tags: Automatic Inspection System Capacitor Automatic Inspection System Aoi Automatic Aoi Machine Vision |

|

Packaging Inspection Equipment For PP Plastic Disposable Food Containers |

|

Straw Defective Product Inspection Machine with Automatic Labeling System |

|

21 Inches Touch Screen Ai Inspection System for Paper Cup Surface Defect Detection |

|

Instant Noodles Bowl Appearance Defect Detection Equipment 300pcs/Min |

|

Intelligent Machine Vision Inspection Systems Aoi Machine For Yogurt Cup |

|

3D HMI Surface Inspection Equipment Machine For Ice Cream Plastic Cup 300pcs/Min |