Intelligent HMI Vision Automatic textile inspection machine with high accuracy

|

|

Product background Textile quality is the lifeblood of textile production enterprises. Quality inspection is an extremely important link in production. How to effectively carry out quality management to find out the problems of product quality in time, reduce the defective rate and improve product quality is very important. At present, most domestic textile enterprises use spinning machines with a high degree of automation, but the surface quality inspection of their products has been stuck in the traditional manual inspection stage due to the lack of matching inspection machinery and equipment. Look for textile surface defects. The manual detection method is easy to cause visual fatigue, has the disadvantages of high labor intensity, low detection efficiency, and the inspection results are easily affected by human subjective factors, and the false detection rate and missed detection rate are high.

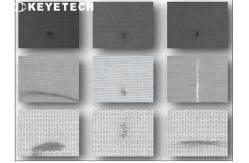

Inspection principle: The introduction of machine vision inspection technology automates the transformation of the assembly line, making the textile production line a fast, real-time, accurate and efficient assembly line, which can greatly improve production efficiency. The automatic detection equipment for textile defects based on machine vision technology integrates machinery, electronics, optics, computer and software engineering. Machine vision detection equipment is used instead of human eyes to complete monitoring, measurement and judgment. It is non-contact, repeatable, reliable and high-precision. , continuity, high efficiency, good flexibility and many other application advantages.

Machine overviews&advantages The inspection machine adopts multiple sets of high-pixel industrial cameras and high-performance stroboscopic light sources to carry out omni-directional visual inspections for product appearance defects. The inspection speed is 200-400m/min. The equipment can realize 7*24 hours of all-weather operation, and it can be online automatically. Eliminate substandard products. The whole set of inspection equipment includes mechanical, visual electronic hardware and inspection system software. The entrance and exit of the equipment are reserved for docking positions to facilitate on-site operations.

Our Advantages |

||||||

| Product Tags: Vision capacitor test equipment HMI capacitor test equipment HMI vision system inspection equipment |

|

GPU Computing Ai Inspection System For Multi Specification Flip Cap |

|

Edible Oil Bottle Cap Automation Products Closure Optical Sorting Machine |

|

Air Compressed Online Reject Defect Product Water Cap Vision Detection Machine |

|

High Precision 0.1mm Cap Vision Detection System 5kw-7kw Power SS 304 Material |

|

Water Cap Closures Visual Inspection System with 6 CCD Industry Cameras |

|

28mm Closure Inspection Machine with HMI Adapt To National Standard |