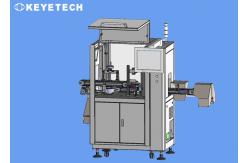

KEYE Ai Based Vision Glass Bottle Inspection Machine For Ordinary Caps

|

|

About the system The flat-bottom cap is suitable for all walks of life, because its own characteristics can bring good sealing and safety to the product packaging bottle, and it is an excellent partner for bottle products. Since bottle body caps are on the market and have a wide range of applications, most manufacturers have a lot of production business on bottle bottom caps, and they have different testing requirements from various angles such as color, model and specifications. On the other hand, bottle caps It is the most direct place for people to touch the contents of the bottle. For the detection of bottle caps, the safety and pass rate can be improved to increase consumers' trust in the brand.

Inspection Standard

Software part: The core algorithm of image processing, after long-term and a large amount of industry experience accumulation, the original system is continuously upgraded and improved, and the entire software system is stable and fast.

Fully consider the functions used by the customer on site, the operation interface adopts a touch screen, the template is easy to add, the detection index parameters, and the accuracy are adjusted.

The user can set the secondary management password according to the level, and perform the authority management according to the login account (for example, the general operation user disables the parameter adjustment authority)

The system equipped with remote function, and it is convenient to add later. Only the equipment needs to be connected to the site. Our company can maintain the equipment and upgrade the system all day after sales

One-key sampling and formulation management. The system completes the initial recipe learning based on all the samples provided by the customer. The later new recipes are simple and easy to learn. The sampling process is completed with one button. Customers only need to call out the corresponding recipes when changing products without other operations.

The system displays real-time production information (qualification rate, total output, speed, etc.), browsing historical production information, exporting and storing functions.

Function *Concave surface detection of bottle caps (1 set of cameras): detect whether there are defects such as deformation, lack of material, black spots, etc., to ensure that the cap is in good condition. *Top surface detection of bottle caps (1 set of cameras): detect whether there are black spots, stains and other defects. *Side detection of bottle caps (4 sets of cameras): detect whether there are defects such as black spots, stains, flashing, lack of material, etc. *Detection speed: 800 pcs/min *Detection range: the appearance and concave surface of the entire plastic cover

Image capture samples Summary The whole system integrates mechanical mechanisms, visual optical hardware and detection system software, defective product rejection and counting devices, and performs 360-degree online collection of the flat bottom cover. The camera transmits the collected image information of the detected product to the industrial control system. The internal software system calculates the picture information fed back by the camera to determine whether there are oil stains, black spots, flash, lack of material, deformation of the cover, etc. inside the flat bottom cover. This project uses 6 high-power cameras, one on the top and one on the bottom, and 4 on the side. The equipment adopts a highly integrated detection and calculation module, which is accurate, fast, simple to operate, and easy to use. It can be freely matched and installed at any position in the assembly line to ensure product quality.

|

||||||||||||||||||||||||||

| Product Tags: Ai Glass Bottle Inspection Machine KEYE Glass Bottle Inspection Machine KEYE ai machine |

|

GPU Computing Ai Inspection System For Multi Specification Flip Cap |

|

CCD Camera Cap Sorting Machine With AI Deeping Learning Algorithm |

|

Edible Oil Bottle Cap Automation Products Closure Optical Sorting Machine |

|

Air Compressed Online Reject Defect Product Water Cap Vision Detection Machine |

|

High Precision 0.1mm Cap Vision Detection System 5kw-7kw Power SS 304 Material |

|

Water Cap Closures Visual Inspection System with 6 CCD Industry Cameras |