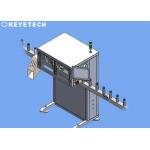

Remote AOI Vision Filled Bottle Inspection Machine For Bitter Wine Bottle

|

|

As a kind of health medicated wine, bitter wine is very popular among consumers, and many manufacturers are keenly aware of the market for this type of liquor. However, when the wine is produced and put into the market, according to international and national standards, the packaging needs to be detected. The bottle label, quality certification, production batch number and other aspects of the wine must be detected. For example, for label errors, products with wrong batch numbers need to be removed in time, and the black spots, stains, gaps, color differences, pores, and deformations of the medicinal bottle itself must be detected.

However, in actual production, the efficiency of manual detection for these small flaws is too low and the accuracy is not high. In response to this type of situation, Keye Tech has used its own years of market experience and has its own understanding and technical system for the packaging inspection industry. It has provided suitable detection solutions for thousands of companies. If your company also needs packaging For testing needs, please contact us and inform us of the samples to be detected.

Detection principle The system transports the bottles to the predetermined station in a stable and orderly manner, and then transmits the captured sample image to the image processing software through the high-pixel industrial camera, compares with the standardized sample and distinguishes the defective product and the good product, and controls the corresponding pneumatic components to reject defective products and collect qualified products.

The software sets the comparison standard for the samples, operators can control the comparison precision and choose the precision standard that best suits themselves, thereby controlling the defect rate and greatly reduce costs.

Examples of sample detection patterns The patterns shown below are all real-time shots in the existing Keye detection system. The details are as follows:

Black spots or impurities in all positions of the bottle.

The detection standards are as follows:

Detection software function: -Open and close the system detection function -Adjustment of detection index parameters and accuracy. -Template sampling and storage, sample detection information save and recall. -Camera image calibration function -The system displays real-time production information (qualification rate, total production, speed, etc.), historical production information browsing, export and save functions. -Permission management based on the login account (such as general operation users disable parameter adjustment permissions) -Operation and adjustment of the mechanical part of the system (Such as open the transmission device, the adjustment of the air valve blow time, and the adjustment of the alarm signal)

Product configuration details

1. Mechanical part

2. Electronic component part:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: AOI Filled Bottle Inspection Machine Wine Filled Bottle Inspection Machine Wine Bottle aoi machine vision | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Surface Defective Inspection System Rejection Machine For Juice Bottles |

|

Automatic Defect Detection System Leak Detector For Filling Cocktail Bottles |

|

Impurity Visual Quality Inspection Machine for Cosmetic Bottle Packagings |

|

Plastic Pharmaceutical Bottle Inspection Machine High Accuracy Sorting |

|

Real Time Detection System For Bottle Surface Defects Based On Machine Vision |

|

Real-Time Dairy Empty Bottle Camera Inspection System With Rejection Valve |