Detection principle

The product is stably ordered to a specific station through the

transfer device, and then the high-pixel sample image taken by the

industrial camera is transferred to the image processing software,

and the standard sample is compared and analyzed to determine the

good product and the defective product, and control the

corresponding pneumatic to remove the defective products and

finally collect the qualified products.

The software will open the sample comparison standard, and the

production personnel on the customer site can control the

comparison accuracy and choose the accuracy standard most suitable

for their own production conditions, thereby controlling the

product defect rate.

Detecting details

Our design plan adopts 11 sets of high-pixel industrial cameras and

high-performance stroboscopic light sources to carry out a full

range of visual detection for the appearance defects of the bottle

body. The detection speed is 120 pieces per minute. The equipment

can realize 7*24 hours of operation, and the unqualified products

can be automatically rejected online.

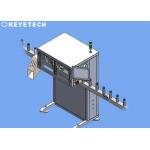

The whole set of detecting equipment includes mechanical parts,

visual electronic hardware and detecting system software. The

entrance and exit of the detecting machine can be integrated with

the on-site conveyor line (see the design drawings for details),

and can be connected to the upstream and downstream production

equipment according to the specific production needs of the

customer. | System operating parameters | | Dimensions | See the design drawings

for details | Power and frequency | 220V 20A 50HZ | | Total power | 5.0~6.0 kw | Air pressure | 0.5~0.8MPa Purify and oil-free | | Working temperature | -20℃ ~ 60℃ | Working humidity | Below 50% relative humidity |

Inspection procedure

Detection standard | Model | Camera number | Detection range | Detection content and accuracy | Detection precision | Speed |

KVIS- SC11 |

1 set |

Bottle mouth | Black spots, stains (different colors) ≧0.2mm | 99% |

120 pcs/min | | Lack of material on cup mouth,overlap≧0.5mm | 99% |

1 set |

Outer bottom part of the bottle | Black spots, stains (different colors) ≧0.2mm | 99% | Penetrating hole (no adhesion in the hole)≧0.5mm | 99% |

1 set |

Inner bottom part of the bottle | Black spots, stains (different colors) ≧0.2mm | 99% | Obviously uneven thickness

(The difference in gray value of local color difference is greater

than 40 or more) | 99% | | Injection point offset≧±0.5mm | 99% | Bottle inner

bottom accumulation of material≧0.5mm | 99% |

4 set point light source |

Bottle mouth outer side part | Uneven bottle mouth

Depth≧0.5mm,length≧1.0mm | 99% | The bottle mouth and lifting ring are crushed

Depth≧0.5mm, length≧1.0mm | 99% | lifting ring dimple, lack of material

Depth≧0.5mm, length≧1.0mm | 99% | Dimples in the inner wall of the bottle mouth

Depth≧0.5mm, length≧1.0mm | 99% | 4set

Integral cavity + point light source |

Bottle outer side part | Black spots, stains (different colors) ≧0.2mm | 99% | | Obviously uneven thickness (including over material on parting

line) (The difference in gray value of local color difference is

greater than 40 or more) | 99% |

System composition

(1) Mechanical part:The mechanical part is the core component of

the system, which carries all the transmission devices and

electronic hardware (industrial cameras,Light source, industrial

computer, touch screen, electrical box, etc.).

The conveyor belt adopts a vacuum adsorption belt to adsorb and fix

the sample on the surface of the belt without sliding, so that the

picture can be accurately taken.

(2) Hardware part:The hardware part includes camera, lens, light

source, high-speed air valve, computer, touch screen and other

electrical equipment. Machining process |