CE Certified Heavy Duty Pallet Racking For Warehouses Storage

|

|

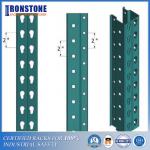

CE Certified Heavy Duty Selective Pallet Racking For Warehouses Storage

In most warehouses, selective pallet racks are commonly seen with heavy-duty storage capacity. Metal pallet racks are designed to have pallets loaded and unloaded using forklifts with high efficiency. Versatile industrial pallet racks are able to store bulky pallet loads following FIFO stock management methods.

Cold-formed storage racks can provide an excellent strength-to-weight ratio with customized sizes. For heavy-duty pallet loads, bolted bracing and baseplates are more recommended for long time usage and warehouse safety. The holes punched on the uprights allow easy and quick beam adjustments catering to personal storage needs.

Beam and upright loading capacity chart

Beam

Beam capacity often refers to a pair of beams' capacity since they work together in each bay. Under vertical pressure and horizontal tension, beams undertake the pallet weight and then transfer that to the uprights. The beam distance between two layers is adjusted to pallet load sizes.

Usually, at each beam level, two pallet positions are designed. In that case, the total weight of two pallet loads must be less than the beam capacity at each level.

Allowable beam deflection formula

Upright

Taking one bay unit as an example, two upright frames placed left and right with connecting beams form a basic storage unit. After the cargo is loaded on the beams, uprights will immediately bear the compression force transfer by-products and other related parts.

The capacity of each upright will hold will be determined by the load weight and the beam length. In this situation, the term "Deflection" is used to measure the vertical beam deviation distance when loaded.

Some important points that may help with your storage system

1. In actual application, the first-level loads are usually placed on the ground for cost-saving.

2. All the load capacity terms we mentioned before refer to static loads.

3. Both beams and uprights' maximum load capacity should be met.

4. All the racks should be installed on the floor fulfilling certain project requests.

5. Racks including frames, beams, and other accessories should be correctly assembled.

6. Capacity redundancy should be left for long-term safe operation and potential damage.

Our product packaging

Our product Certified

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: CE Certified Selective Pallet Racking Adjustable Mobility Selective Pallet Racking OEM Heavy Duty Selective Pallet Racking | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High Capacity Heavy Duty Teardrop Steel Rack for Industrial Storage |

|

Q355 US Standard Steel Warehouse Pallet Rack |

|

100% Selective Teardrop Racking System For Universal Application |

|

Warehouse Roll Formed Teardrop Pallet Racking System |

|

New Teardrop Style Rack Applying to US Standard 40”*48” Pallets |

|

3.0”*3.0” Teardrop Columns Pallet Rack |