Easy Integrating Gravity Push Back Rack For High Efficient Storage

|

|

High-Density Effective LIFO Push Back Pallet Rack System for Industrial Storage

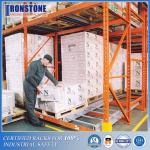

Push-back racking is a high-density pallet storage system using a selective racking structure with a track and cart system. Pallets are placed on trolleys and pushed backward to create storage from 2 to 6 pallets deep.

Pallets are placed on nested trolleys or pallets that can be pushed backward along the racks themselves. The rails are inclined and fed by gravity so that the most recently added load is always at the front of the rack. The pallets are easily loaded and unloaded for "LIFO" (last in, first out) rotation.

Picking is done by removing the front pallets, which allows the back of the pallets to advance. The advantage of the push-back rack-over-drive or rack-over-drive type is the ease of access. Each pallet on each level can be a different SKU without having to use only the entire lane and can provide up to 90% more storage space than selective racking.

How does push-back pallet rack work?

In push-back racking, the racking uses trolleys that move along inclined tracks. Each pallet is loaded onto the trolley from the front of the system. To use the next pallet, the first is pushed slowly until it is aligned with the next available trolley. When the previous pallet is unloaded, the next pallet slides to the front for picking.

Characteristics of Push Back Pallet Rack System:

In short, push-back racking increases storage density and allows a high level of storage space in a much smaller area. When a new pallet is added, the current load is pushed back and the new pallet takes its place at the front.

Push racking is a great option when you are looking for a medium to high density storage solution. It allows for more efficient use of space as the storage area is compressed into a tighter area than traditional standard pallet racking, which may require many separate rows to store the same number of pallets.

Push-back pallet racking combines the density of drive-in racking and single lane of selectivity. Wheeled trolleys are stacked in the picking aisles of each lane. A pallet is placed on the top trolley, then the next pallet is loaded and the forklift gently pushes it back to reveal the trolley below. This process continues until all the trolleys have been used and the last pallet is placed on the rails. When the pallets are picked up, the back pallets automatically flow forward, producing an efficient process.

|

||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: LIFO Push Back Racking System 1000kgs Roll Back Racking LIFO pallet rack back | ||||||||||||||||||||||||||||||||||||||||||||

|

LIFO Live Storage Push Back Pallet Racking With Versatility and High Compatibility |

|

Safe Loading And Retrieval Push Back Racking Storage System |

|

Flexible Push Back Racking For Cold Storage |

|

Warehouse Push Back Pallet Racking System For Flexible Storage |

|

Immediate Access And Visibility Push Back Rack System With Picking And Loading |

|

Easy Retrieval Push Back Rack System For LIFO Inventory Rotation |