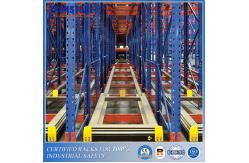

Simple Assembly Heavy Duty Gravity Push Back Rack For High-efficient Operation

|

|

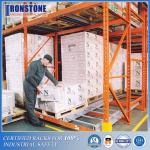

Heavy Duty Push Back Pallet Rack Storage Systems For High-Density Storage Solutions

Push back rack offer high-density storage similar as drive in rack, but with more selectivity for multiple SKUs situation, because of wheeled carts nested on inclined rails provide dynamic storage & retrieval of each pallet position, It saves more time to pick products without driving trucks into rack systems.

First pallet is loaded onto top carts in each lane, then next pallet will push in front of first pallet till it rests on the second cart by forklift operator, the process will be repeated until each storage lane is full. To unload the lane, last pallet will be out first and the others roll back forward down to the picking face until empty the lane.

Main Benefits

►High storage density as well as more selectivity.

►High utilization of space for storage capacity.

►Fast inventory rotation.

►Forklifts don’t need enter rack systems for operating, which lead to less rack damage.

|

| Product Tags: AS4084 Push Back Pallet Rack Push Back Pallet Rack 1500kgs 1500kgs High Density Storage System |

|

LIFO Live Storage Push Back Pallet Racking With Versatility and High Compatibility |

|

Safe Loading And Retrieval Push Back Racking Storage System |

|

Flexible Push Back Racking For Cold Storage |

|

Warehouse Push Back Pallet Racking System For Flexible Storage |

|

Immediate Access And Visibility Push Back Rack System With Picking And Loading |

|

Easy Retrieval Push Back Rack System For LIFO Inventory Rotation |