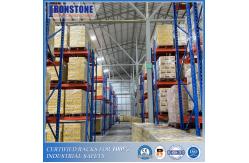

Warehouse Pallet Racking Systems

|

|

Warehouse Pallet Racking Systems

The warehouse pallet racking systems is the most widely used pallet racking system, providing single deep pallet storage. It is called “selective” because selectivity is its prime characteristic. Configured as a single row or back-to-back row, the selective pallet racking system makes every pallet accessible without moving away other pallets.

More details about warehouse pallet racking systems

Features

Material handling equipment: All types of forklifts.

Maintenance

The system requires little maintenance. When performing the inspection, check for beams, uprights, anchors, and accessories.

How to avoid excessive beam deflection?

Usually, besides an accidental collision, excessive beam deflection is mainly caused by overweight load or nonuniform loads. The engineered beam capacity refers to a uniformly distributed load. Therefore, loaded pallets should be in uniformly distributed weight and placed symmetrically and evenly in the bay.

In addition, overloading is prohibited. Otherwise, beams are easy to bow beyond the deflection limit designed for the maximum load, leading ta damage of beams, or even an increased risk of cargo falling or personnel injury.

How to define the maximum permissible load of beams with A deflection limit?

When the professional engineer designs a beam for industrial steel storage racks, the maximum acceptable deflection is included in the calculation. That is to say, based on uniform loading, when the beam reaches its deflection limit, 1/180 of beam length, it also comes to its maximum permissible load.

However, it is necessary to mention here that the deflection limit is a reference for defining the maximum permissible load of racks, but not a parameter that guarantees the integrity of beams or racks. Even within the limit, racks also need careful inspections. It’s assumed that beam length divided by 180 is a cut-off point at which people can find the deflection of a beam surpassing its governed limit.

Our Factory and Workshops

Ironstone owns all kinds of production equipment, like advanced rolling machines, cutting machines, automatic punching machines, welding lines, automatic anti-corrosion epoxy powder painting lines, etc. Of course, we have skillful workers who operate and manage the whole production. |

||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 75mm Selective Pallet Racking System Q355 Steel Pallet Shelving Q355 Commercial Pallet Racking | ||||||||||||||||||||||||||||||||||||||||||||

|

American RMI Certificated Heavy Duty Warehouse Pallet Rack |

|

Warehouse Pallet Racking System with high space utiliztion |

|

High Bay Warehouse Pallet Racking Systems |

|

RMI Certified American Standard Steel Made Teardrop Rack |

|

Highly Engineered US Standard Teardrop Rack With Seismic Calculation |

|

Compatible Cost-Effective Teardrop Pallet Racking System |