Customization Machining Quartz Glass Parts Geometries With Internal External Thread

|

|

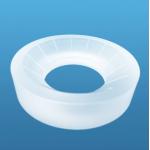

Customization Machining Quartz Glass Parts With Internal And External Thread

With the aid of the latest CAD / CAM software systems combined with cutting-edge equipment and expert CNC machine operators, we have the ability to manufacture the most complex geometries and tightest tolerances.

Product maintenance advice for quartz glass:

Quartz glass is super-cooled liquid. It only has softening temperature range. The higher the temperature, the smaller the viscosity, it is easier to deform. If the quartz glass parts is used at a temperature of 1100 ℃ or more for a long time, the furnace temperature can be increased to 1200 ℃ before starting to use. Rotate the tube for 90°every two hours and repeat this for 20-30 hours. Then put it into work, this way can reduce the deformation.

Hydrofluoric acid and hot phosphoric acid at 200℃ will obviously corrode quartz glass.

Rich experience in quartz glass industry Strong technical force in processing and application Integrity and Quality Assurance |

| Product Tags: Customization Machining Quartz Glass SGS Machining Quartz Glass Geometries Machining Quartz Glass Parts |

|

Machining Quartz Glass High Precision Quartz Flange High Temperature Resistance |

|

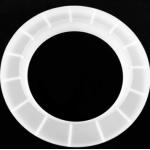

Machining Quartz Glass White Customized Fused Quartz Ring |

|

Customized High Purity Quartz Parts And Components Oem |

|

Customized ISO 9001 Quartz Ring Cnc Milling Machined Parts |

|

Frosted Quartz Glass Plate With Multibore For Laboratory Water Swirling Device |

|

High Precision Custom Quartz Glass Cuvettes Quartz Flow Cell Analysis Instrument |