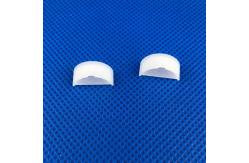

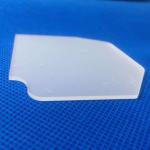

High Precision Machining Quartz Glass Component CNC part for Optical Equipment

|

|

High-precision Machining Quartz Glass Component Used In Optical Equipment

Because quartz glass has unique comprehensive properties that other materials do not have, that is, very low thermal conductivity, excellent thermal vibration resistance, high deformation temperature and softening temperature, very low thermal conductivity, and very low dielectric loss, it is often made into parts of various shapes and widely used in various scenes.

Quartz parts, through the CNC machining center, realize the precise and difficult machining of the curved surface, the inclined surface, the groove area, the spherical surface, the cylindrical surface, the aperture, and the cone angle of the product. The minimum aperture can reach 0.8 mm, and the minimum geometric tolerance can reach ±0.02 mm. The finish, surface shape, roughness and raw materials can be customized according to customer requirements. High product accuracy and long service life.

Rich experience in quartz glass industry Strong technical force in processing and application Integrity and Quality Assurance |

| Product Tags: High Precision Machining Quartz Glass Machining Quartz Glass CNC Part CNC Machining Quartz Glass Component |

|

Customized High Purity Quartz Parts And Components Oem |

|

Customized ISO 9001 Quartz Ring Cnc Milling Machined Parts |

|

Frosted Quartz Glass Plate With Multibore For Laboratory Water Swirling Device |

|

High Precision Custom Quartz Glass Cuvettes Quartz Flow Cell Analysis Instrument |

|

Cnc Machined Diffuser Machining Quartz Glass Shot For Sputtering Coater |

|

Custom Grinded Fused Quartz Optical Platform For Spectrometer |