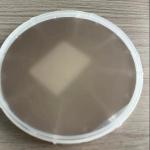

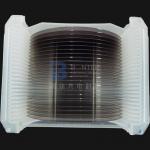

Thin Films, Mighty Applications: LiTaO3 in Biomedical Sensing In the realm of biomedical sensing, LiTaO3 emerges as a

game-changer, driven by its pyroelectric effect and our commitment

to ultra-thin wafers. With a wafer-level thickness as fine as 20um

and diameters extending up to 4 inches, these LiTaO3 wafers set a

new standard in precision. The pyroelectric effect, when harnessed

in biomedical sensors, ensures accurate temperature measurements

vital in various medical applications. From patient monitoring to

diagnostic tools, LiTaO3's thin film becomes the foundation for

innovations that prioritize sensitivity and reliability in the

biomedical field. Diameter | 76.2±0.2mm | 100±0.2mm | 150±0.2mm | Primary Flat | 22±1mm | 32±1mm | 47.5mm, 57.5mm, Notch | Orientation | 36°Y, 42°Y, X-112°Y, Y, Z | Thickness | 0.02mm~1.0mm | 0.02mm~1.0mm | 0.05mm~1.0mm | Surface finish | Single / Double side polish / Double side lapped | TTV | < 1~5µm | BOW | ± (20µm ~40um ) | Warp | <= 20µm ~ 50µm | LTV (5mmx5mm) | <1.5 um | PLTV(<0.5um) | ≥98% (5mm*5mm) with 2mm edge excluded | Polished side Ra | Roughness Ra<=5A | Back Side Criteria | Roughness Ra:0.5-1.0µm, GC#1000 | Scratch & Dig (S/D) | 20/10, 40/20, 60/40 | Edge Profile | Compl't with SEMI M1.2@with GC800# .regular at C typed | Cracks, saw marks, stains | None |

Crystal Structure | Trigonal, Space group R3c, Point group 3m | Cell Parameters | a=5.154Å, c=13.781Å | Melting Point | 1650℃ | Curie Temperature | 607℃ | Mohs Hardness | 5.5 | Density | 7.46g/cm3 | Dielectric Constants | ε11/ε0:51.7 | ε33/ε0:44.5 | Elastic Stiffness Coefficients | CE11:2.33(×1011N/m2) | CE33:2.77(×1011N/m2) | Piezoelectric Strain Constants | d22:2.4(×10-11C/N) | d33:0.8(×10-11C/N) | Transmission range | 400-4500nm | Electro-optical coefficients | r33=30.4pm/V | Refractive index at 632.8nm | no=2.176, ne=2.180 |

|