Unlocking Lithium Tantalate On Insulator ( LTOI ) For Advanced Photonic Applications

|

|

Unlocking the Potential of Lithium Tantalate on Insulator (LTOI) for Advanced Photonic Applications

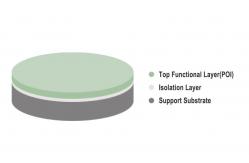

LTOI stands for Lithium Tantalate on Insulator, is a specialized substrate technology used in the field of integrated photonics. It involves the transfer of a thin layer of lithium tantalate (LiTaO3) crystal onto an insulating substrate, typically silicon dioxide (SiO2) or silicon nitride (Si3N4). LTOI substrates offer unique advantages for the development of compact and high-performance photonic devices.

LTOI substrates are created through a bonding process where a thin layer of lithium tantalate crystal is transferred onto an insulating substrate. This process can be achieved through various techniques, including wafer bonding or ion-cutting, ensuring a strong bond between the layers.

LTOI substrates offer unique advantages for advanced photonic applications. Their utilization in electro-optic modulators, waveguides, nonlinear optical devices, sensors, quantum photonics, and integrated photonic circuits demonstrates the broad range of applications and the potential for pushing the boundaries of integrated photonics technology.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Photonic Lithium Tantalate On Insulator LTOI Piezoelectric Wafer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Stoichiometric LiTaO3 Wafers Ideal Material for Optical Modulators and Frequency Converters |

|

3" 4" 6" Single Crystal Quartz With Customized Wafers And Their Outstanding Material Properties |

|

3" 4" 6"Single Crystal Quartz Wafers For High Temperature Applications Customized Orientation Options With 3 Inch And 4 Inch Sizes |

|

3 Inch And 4 InchCustomized Orientation Options For Single Crystal Quartz Wafer High Temperature |

|

Stoichiometric LiTaO3 Wafers The Ultimate Choice for High-Frequency Electronics |

|

2" 3" 4" 6" Lithium Tantalate Wafers Ultimate Solution For Piezoelectric Applications |