Product Description:

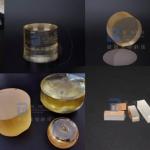

8-inch LiNbO3 wafers refer to the specific size of LiNbO3 crystal

substrates commonly used in the fabrication of optoelectronic

devices and integrated circuits. These wafers are made from

high-purity lithium niobate crystals and offer several advantages

due to their larger size. Here is a description of 8-inch LiNbO3

wafers:

- Size: 8-inch LiNbO3 wafers have a diameter of approximately 200

millimeters (8 inches), making them larger than smaller-sized

wafers like 4-inch or 6-inch wafers. The larger surface area of

8-inch wafers allows for higher device density and increased

production efficiency.

- Thickness: The standard thickness of 8-inch LiNbO3 wafers ranges

from 0.5 to 1 millimeter. However, custom thicknesses can also be

obtained based on specific application requirements.

- Crystal Orientation: 8-inch LiNbO3 wafers can be cut and oriented

along different crystal planes, typically the Y- and X-cut

orientations, which are commonly used in many optoelectronic

devices. However, other crystal orientations may also be available

depending on the specific application needs.

- Advantages: The larger size of 8-inch LiNbO3 wafers offers several

advantages:

Increased Device Capacity: The larger surface area allows for a

higher number of devices and integrated circuits to be fabricated

on a single wafer, thereby improving production capacity and yield.

Enhanced Integration: With a larger area, 8-inch wafers enable

higher device integration and improved performance due to the

availability of more real estate for components and interconnects.

Improved Uniformity: The manufacturing process for larger wafers

often results in better consistency and uniformity across the

wafer, contributing to improved device performance and yield.

- Availability: 8-inch LiNbO3 wafers are commercially available from

various specialized semiconductor material manufacturers. These

suppliers provide ready-made 8-inch wafers or offer customization

options to meet specific application requirements.

Applications:

8-inch LiNbO3 wafers find applications in various fields where

their unique optical and electro-optic properties are utilized. For

example: Optical Modulators, Frequency Conversion, Acousto-Optic

Devices, Integrated Optics, Nonlinear Optical Devices, Optical

Sensors.

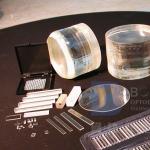

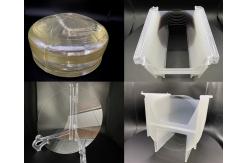

Packing and Shipping:

LiNbO3 Wafers should be packaged and shipped in accordance with the

following guidelines:

- LiNbO3 Wafers should be packaged in an antistatic bag.

- The package should be padded with cushioning material to protect

against shock.

- The package should be clearly labeled with the product name and the

contents of the package.

- The package should be sent by a reputable courier service.

- The package should be tracked and insured.