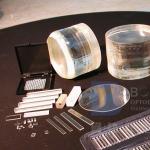

Pyroelectric Free Reduced LiNbO3 Wafer 128Y Cut SAW Grade

|

|

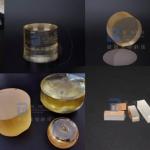

Pyroelectric Free Black LiNbO3 Wafer 128Y-Cut SAW Grade

The reduction technique is used to produce black lithium niobate (LiNbO3). Black LiNbO3 wafer has a high ability to neutralize charges even if the electric potential occurs instantaneously. The pyroelectric effect of LN wafer is almost eliminated and the transmittance is significantly reduced. The piezoelectric properties of black lithium niobate wafers are no different from those of standard wafers. Therefore, black reduced lithium niobate wafers are widely used to produce higher frequency surface acoustic wave devices.

BonTek is proud to announce that we can offer 3 ", 4 ", and 6 "black LN wafers for all cutting angles.

Acceptance Check

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Pyroelectric Free LiNbO3 Substrate Reduced Lithium Niobate Wafer SAW Grade Lithium Niobate Substrate |

|

4 Inch LiNbO3 Wafer Polished 5mol% MgO Dope For Magnetic and Optical Applications |

|

4 Inch LiNbO3 Wafer Polished 0.25mol% Er Dope Or 5mol% MgO Dope For Optical Applications |

|

Lithium Niobate LN LiNbO3 Piezoelectric Crystal X 163Y 36Y 10Y Z 41X Cut |

|

Ra Roughness 1nm LiNbO3 Wafer Visible Optical Linbo3 Crystal |

|

4 Inch LiNbO3 Wafer MgO Dope Optical Wafer Crystal High Temperature Resistance |

|

Piezoelectric LiNbO3 Wafer Substrate 128Y Cut With Orientation Flat Notch |