8 Inch Lithium Niobate Wafer

|

|

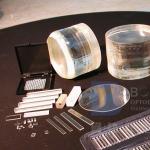

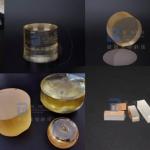

8 Inch 128Y-cut Black LiNbO3 Wafer SAW Application IDT use Ra Roughness 1nm

The reduction technology is used to produce Black Lithium Niobate (LiNbO3) which has high ability to neutralize electrical charges even if the electrical potential occurs instantaneously. The pyroelectric effect for the reduced LN wafers was almost eliminated and the transmittance decreased considerably. The black LiNbO3 wafer shows no difference in piezoelectric properties from standard wafers. As a result, black reduced lithium niobate wafers are widely adopted to produce higher frequency SAW devices.

BonTek is proud to announce that we can provide the black LN wafers in 3 inch, 4 inch, 6 inch for all cut angles! For 128°Y and Z-cut up to 8 inch diameter.

FAQs:

A: We look at ourselves as the piezo wafer specialist. We are the very first to work with Single Crystal Quartz in China about 30 years ago. Then gradually we step in the field of LiNbO3, LiTaO3, Quartz glass, LGS, CTGS etc. Especially, if you are looking for a piezo quartz supplier, we are the ultimate choice! We export millions of quartz blanks each year because we master the AT, SC and IT cuts with superior angle precision.

A: Yes, of course. We can fabricate as per your request. In addition, we are so experienced with piezo wafers that we can provide you relevant suggestions if you are not 100% sure about your choice. Besides, we do have some standard wafers in stock, please check with us.

A: Yes, we would suggest you go with the courier agent you are most familiar with (DHL, FedEX, UPS etc.). We can ship via your account. And, of course, we will pack the products safely in acceptable size to help you save the shipping cost. If you need us to take care of the freight, it’s also not a problem. We also have good discount with the international courier companies.

A: The wafer products are fragile and sometimes expensive. The last thing, as the manufacturer, we want to see is the products we make were damaged during courier. As a result, we will pack the wafers adequately and put them in a proper carton filled with buffer sponge. However, accidents are inevitable sometimes. So, please follow the “Acceptance check” steps shown in the drawings below. If the unwanted happened, we will either give the replenishment or refund if you follow the checking steps.

A: Sure. Factory inspection is important for large quantity purchase and long-term cooperation. Face to face discussion is what we mostly confident with. During the past years, big names around the world have witnessed our progress in factory build-up. These days, due to the Covid-19 pandemic, we also had the experience of videoconferencing with global buyers.

Acceptance Check

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 128Y-cut Lithium Niobate Wafer 8 Inch Wafer 1nm 8 Inch Lithium Niobate Wafer |

|

4 Inch LiNbO3 Wafer Polished 5mol% MgO Dope For Magnetic and Optical Applications |

|

4 Inch LiNbO3 Wafer Polished 0.25mol% Er Dope Or 5mol% MgO Dope For Optical Applications |

|

Lithium Niobate LN LiNbO3 Piezoelectric Crystal X 163Y 36Y 10Y Z 41X Cut |

|

Ra Roughness 1nm LiNbO3 Wafer Visible Optical Linbo3 Crystal |

|

4 Inch LiNbO3 Wafer MgO Dope Optical Wafer Crystal High Temperature Resistance |

|

Piezoelectric LiNbO3 Wafer Substrate 128Y Cut With Orientation Flat Notch |