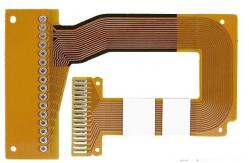

1 To 6oz Flexible Pcb Board

|

FPCA,FPC Assembly Manufacturer,flexible PCB factoryOur Services

We can provide one-stop service:

1. PCB circuit boards. 2. E-test. 3.Electronic components purchasing. 4. PCB assembly: available on SMT, BGA, DIP. 5. PCBA function test. 6. Enclosure assembly. Component Assembly - The service mount capability and trough hole

that this design offers is a remarkable electrostatic and

protective packaging. Air Gap - The technology of flexible circuits rapidly increased the

flexibility that is mainly achieved by layers with one main

advantage “unbinding”. This is an essential aspect of the flexible

circuit assembly, allowing the layer to freely flex. Controlled Impedance - is responsible for increasing the signal

switching speeds used transmission lines. Today’s designs is

increasing the speed and minimizing the electrical reflections.

It's help to ensure no errors between the transitions and the track

interconnections. On the other hand, a perfectly designed and

optimized controlled impedance can allow great control of the

material of the cable and its physical dimensions. The controlled

impedance in order to uniform in both thickness and electrical

properties that is not a barrier for the industry. Penalization - allows the circuit to be durable in components

assembly. Once the panel is completed the circuit is ready for the

end product. Pressure Sensitive Adhesives (PSAs) - are used in projects and

applications that a portion of the circuit has to be extra secured

to a specific condition or location in the end product. The

assembly process includes a releasing of the abradant liner and the

adhesive with remains exposed is allowing the manufacturer to press

the circuit in its place and keep it durable for use. Shielding - when there is a demand to limit electrostatic and

electromagnetic interferences that securing is applied. The shielding can be solid or electromagnetic. Both of the materials are insulating signal lines and any noise. Manufacturing of Flexible Printed Circuit Board ___________________________________________ FPC is usually created by a photolithographic one sheet a time,

also more efficient way is adopting R oll T o R oll ( RTR ). 1. Shearing: Crop the row material. 2. Computer Numerical Control (CNC): CNC is the drilling process. 3. Plating hole: Plate copper on hole. 4. Dry film lamination: create an etching layer of resistance. 5. Exposure: create an exposure area. 6. Development:The exposure area is polymerized and hardened by UV-rays. 7. Etching:remove the non-exposure area by chemical reaction. 8. Stripping:circuit pattern exposed. 9. Automated Optical Inspection (AOI):checks the quality of the printed board. 10. Coverlay pre-lamination:the board is covered with an insulation layer called “overlay”. 11. Hotpress:Bond between the overlay and the copper layer. 12. Metal finish: Coated to protect the terminal function. 13.Test: test the finished design.

How Senyan-PCB Stands Out from Other FPC Competitors? 1. High-quality PCB raw materials with flexibility, ensuring the

quality of the source. Cover Film: TaiFlex, APLUS, RCCT Material: Dupont, TaiFlex PI reinforce: UBE, TaiFlex, SKC Electromagnetic membrane: Fang Bang, Toyo, Sankei 2. Professional research and seasoned development department in FPC production and quality. 3. Different end types as CTP, flexible PCB led strip, Biological recognition, automotive, and more… 4. Provide the best quality end-design product based on reduced fabricating costs. 5. Team of professionals available at your services 24/7. 6. Strictly following the IPC standards. 7. Fast delivery time. Our service: * PCB & PCBA OEM/ODM and clone service * Sign NDA (Non-disclosure Agreement) for All customers * MOQ : 1PCS is available for us * One-stop turnkey solution * One Year Product Warranty * Products are 100% quality checked in both functionality and cosmetic. PCB or PCBA Files Requests: 1. Gerber files of the bare PCB board 2. BOM (Bill of material) for assembly (please kindly advise us if there is any acceptablecomponents substitution.) 3. Testing Guide & Test Fixtures if necessary 4. Programming files & Programming tool if necessary 5. Schematic if necessary SMT Manufacturing Capability

Detail For PCB:

Q1. Can I have a sample order to test it? Q2. What about the lead time? Q4. How do you ship the goods and how long does it take to arrive? Q5. I have no drawing, how to process it? Q6. Is it OK to print my logo on product? Q7: Do you offer guarantee for the products? Q8: How to deal with the faulty? |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 6oz Flexible Pcb Board 1oz Flexible Pcb Board ISO14001 flexible pcb assembly | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Multilayer FPC Electronics PCB Board 0.15mm ENIG FPC Connector For Electric Products |

|

Custom 0.13mm Double Layers FPC Circuit Board With Immersion Gold OSP Surface Finishing |

|

Senyan Custom 0.11mm - 0.5mm Flexible Circuit Board FPC PCB Board 2 - 32 Layers |

|

FPC Flexible PCB Board Circuit Board HASL-F Surface For LCD Display |

|

1 To 6oz Flexible Pcb Board |

|

Polyimide FR-4 Flexible Printed Circuit Board |