Electrolytic Self Adhesive Copper Shielding Foil For Rf Cage

|

|

Electrolytic Self Adhesive Copper Foil Sheets Shielding For Rf Cage

Description:

In an electrodeposited copper manufacturing process, the copper foil is deposited on a titanium rotating drum from a copper solution where it is connected to a DC voltage source. The copper surface on the drum side is smooth while the opposite side is rough. The slower the drum speed, the thicker the copper gets and vice versa. The copper is attracted and accumulated on the cathode surface of the titanium drum. The matte and drum side of the copper foil go through different treatment cycles so that the copper could be suitable for PCB fabrication.

Application

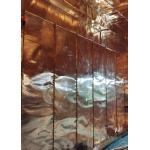

ED Shielding Copper Foil is pretty popular in rf cage installation, because of its super width 1320mm, engineers can make wider copper panels and less copper panels connections can make less gaps between two panels. It will have better shielding frequency than more gaps rf cage.

After-Service:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: self adhesive copper shielding foil electrolytic copper shielding foil rf cage conductive shielding foil | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

0.07mm Copper Sheet Coil Emc Emi Rf Shielding On Reinforced Wall |

|

Emi Rolled 0.1mm Copper Foil Shielding High Purity |

|

0.2mm Copper Emi Shielding Sheet Roll High Purity |

|

0.2mm Thickness Sheet Roll Copper Foil Shielding Mri Room Installation |

|

Electrodeposited Copper Foil Emi Shielding 3oz 1320mm Width |

|

2oz Electrodeposited Copper Foil Shielding 1320mm Width Pure |