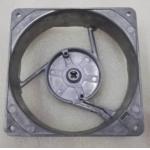

TS16949 Mechanical Arm Robot Light Weight Robotic Lifting Arm

Injection Molding

Specification:

| Product name | Robot parts |

| Specification | |

| Unit weight | 0.6KG |

1. Magnesium alloy arms should have large bearing capacity, good

rigidity and light weight.Product Description:

2. The movement speed of the arm is appropriate and the inertia is

small.

3. Magnesium alloy manipulator has the characteristics of light

structure and high load/weight ratio, so it has lower energy

consumption, larger operating space and high efficiency. Its

response is fast and accurate, and it has many potential

advantages.

Features:

Magnesium and magnesium alloy materials have significant advantages

in reducing weight, improving robot maneuverability, and endurance

due to their light weight and high specific strength. They are one

of the most ideal materials for manufacturing robots.

The lightweight of robot materials can greatly improve its

maneuverability and increase its work efficiency, highlighting the

robot's advantages in reducing motion inertia, improving operation

speed and motion accuracy. The development of high-performance

magnesium alloy and its forming and processing technology for

manufacturing robot parts is of great significance for reducing the

quality of robot moving parts, improving the accuracy of motion,

and achieving energy saving.

Advantage:

FAQ:

1. Q:Are you a factory or a trading company?

A:We are a factory which has been focus on Magnesium alloy deep

processing lightweight field & semi-solid injection molding of

Magnesium alloy for more than 16+ years.

2. Q: Is there quality control on all production lines?

A: Yes, all production lines have adequate quality control.

3. Q: Has the company established and implemented a standard

procedure for purchasing contract review and approval?

A: Yes, with written standard procedures.

4. Q: Is there a procedure to conduct random product inspections

after final packaging?

A: Yes, with clear standard and written inspection records.

5. Q: How can I get a quotation?

A: Please kindly send us following information 1) Product drawings

by STEP/STP/PRT/PDF/IGS format etc. 2) Material, size and surface

treatment request. 3) Required quantity. Normally,the quote will be

offer in 1-6 hours. :)

6. Q: What is your payment terms?

A: T/T, Western Union, etc.