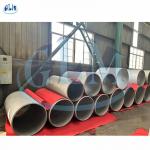

ASME Certificate Vessel Head Rolled Shells for Performance

|

Product Description:Process: 1. Rolling: A flat metal plate is fed through a plate roll (or press brake) to form it into a cylindrical shape. 2. Tack Welding: Once the desired curvature is achieved and the edges are brought together, small, intermittent welds (tack welds) are applied along the seam. These tacks are temporary and primarily serve to hold the rolled shape in place for subsequent operations. ions. Technical Parameters:

Applications:Pressure vessels: The main body (shell) of pressure vessels where high strength and leak-tightness are critical. Pipes: Large diameter pipes used in various industries. Tanks: Storage tanks for liquids, gases, or bulk solids. Structural elements: Cylindrical components that need to bear significant loads. Ducting and stacks: Industrial exhaust stacks, large diameter ducting.

Products:

FAQ:Q: What is the Brand Name of the Pressure Vessel Dished Head product? A: The Brand Name is GLM. Q: What is the Model Number of the Pressure Vessel Dished Head product? A: The Model Number is Cap. Q: Where is the Pressure Vessel Dished Head product manufactured? A: The product is manufactured in China. Q: What certifications do the Pressure Vessel Dished Head product have? A: The product is certified with ASMEU, R, U2, PED, ABS, TUV, NB, and ISO. Q: What is the minimum order quantity for the Pressure Vessel Dished Head product? A: The minimum order quantity is 1. |

|

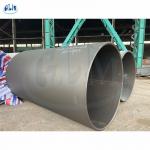

Thickness 20 mm Stainless Steel Pressure Vessel Shells |

|

Titanium Grade Dished Head for Cold Forming |

|

Formed Shell & Hemispherical Heads For Separator Vessel |

|

1950mm Diameter Pressure Vessel Dished Head With Hydrostatic Test Inspection |

|

End Pressure Vessel Dish For Thermal Energy Storage Tanks |

|

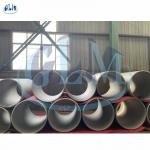

Stainless Steel 304/304 L Rolled Shells Thickness 40mm |