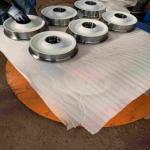

Hot Die Forging Railway Axle Material Ready For Machining Requirements

|

Product Description:The Steel Rail Wheels product offers a reliable solution for various industrial applications requiring rugged steel rail wheels. Manufactured from EN1N material, which is equivalent to 070M20 / AISI 1020, these train wheels are known for their durability and strength. The production process involves either hot die forging or open-die forging, ensuring the highest quality and consistency in the final product. With custom dimensions based on customer drawings, these railroad steel wheels can be tailored to specific requirements and applications. Optional services such as ultrasonic testing (UT), magnetic particle inspection (MPI), heat treatment (normalizing or quenching and tempering), rough or semi-machined axle blanks, and certification per EN10204 3.1 or 3.2 are available to meet stringent quality standards. One of the key advantages of these steel rail wheels is their good machinability, toughness, and ductility. The reliable grain flow in the material ensures superior performance and longevity. Moreover, the customization options allow customers to create tailor-made solutions for their specific needs. Features:

Technical Parameters:

Applications:kingrail Steel Rail Wheels are versatile products that find applications in various scenarios across the railway industry. These solid steel rail wheels are designed to meet the highest standards and are suitable for a wide range of uses. One key application scenario for these railway forged wheels is in locomotives. The robust construction and reliable performance make them ideal for locomotive axles, ensuring smooth and efficient operation of the trains. Freight cars also benefit from the use of kingrail Steel Rail Wheels. The durable and high-quality construction of these wheels ensures safe and reliable transportation of goods, even in demanding conditions. Passenger coaches rely on sturdy and dependable components like train wheels and axles. The kingrail Steel Rail Wheels provide the necessary strength and durability to support the smooth and safe movement of passenger trains. Light rail and metro vehicles also make use of these solid steel rail wheels for their axles. The precision engineering and high-quality material ensure a stable and efficient performance, crucial for urban transit systems. Manufactured in China, these steel rail wheels meet ISO certification standards, guaranteeing quality and reliability. Customers can order these wheels in custom dimensions based on their specific requirements, ensuring a perfect fit for their applications. With a flexible minimum order quantity and negotiable pricing, these steel rail wheels are accessible to a wide range of customers. The payment terms include L/C, D/A, D/P, T/T, Western Union, and MoneyGram, offering convenience and flexibility in transactions. Furthermore, optional services such as Ultrasonic Testing (UT), Magnetic Particle Inspection (MPI), and Heat Treatment are available to enhance the performance and durability of the wheels. Certification per EN10204 3.1 or 3.2 can also be provided for compliance purposes. In conclusion, kingrail Steel Rail Wheels offer a reliable and efficient solution for various railway applications, from locomotives to light rail vehicles. With a high supply ability and quick delivery times, these wheels are a dependable choice for customers seeking quality and performance in their railway components. Support and Services:Our Product Technical Support and Services for Steel Rail Wheels include: - Comprehensive product knowledge and expertise to assist with any technical inquiries - Troubleshooting assistance for any issues related to the steel rail wheels - Maintenance tips and guidelines to ensure optimal performance and longevity of the product - Training programs for proper handling and installation of the steel rail wheels - Warranty support and assistance with claims and returns Packing and Shipping:Product Name: Steel Rail Wheels Description: High-quality steel wheels designed for use on railway tracks. Package Includes: Set of 4 steel rail wheels Package Dimensions: 12" x 12" x 6" Package Weight: 20 lbs Shipping Method: Standard Ground Shipping Shipping Cost: Calculated at checkout FAQ:Q: What is the brand name of the steel rail wheels? A: The brand name is kingrail. Q: What is the model number of the steel rail wheels? A: The model number is 200mm. Q: Where is the place of origin for the steel rail wheels? A: The steel rail wheels are manufactured in China. Q: What certifications do the steel rail wheels have? A: The steel rail wheels are certified with ISO. Q: What are the accepted payment terms for purchasing the steel rail wheels? A: The accepted payment terms include L/C, D/A, D/P, T/T, Western Union, and MoneyGram. |

||||||||||||||||

| Product Tags: Ready for Machining Railway Axle Hot Die Forging Railway Axle Railway Axle |

|

Customized Design Railway Suspension System In Passenger Cars |

|

Custom Forged Alloy Wheels Experience Unmatched Style and Performance |

|

Kingrail Steel Rail Wheels For Open Top Cart Hay Top Notch Performance And Reliability |

|

Easy Maneuverability Reinforced Rail Track Trolley For Heavy Industrial Loads Standard Track Gauge 1435 Mm |

|

Manufacturing Process Heat Treatment Rail Wheels And Axles EN 13261 Europe Standards |

|

Round Vehicle Wheels Forged Alloy Steel For Ultimate Corrosion Protection In Black Or Silver |