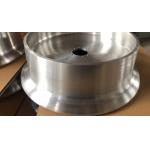

OEM Aluminum Alloy Wheels , T6 Powder Coating Forging Alloy Wheels ISO Certificate

|

|

OEM Aluminum Alloy Wheels , T6 Powder Coating Forging Alloy Wheels ISO Certificate

The raw material is T6-6061(or 6082,or 6110), main production

process is Forging--Spinning---Heat treatment---CNC----Powder coat

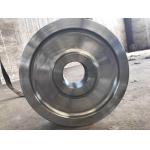

The is othermal forging forming method of 2024 aluminum matrix

composite splint forgings, the steps are: first upsetting the

billet on the free forging hammer, and then drawing it; After

drawing, the blank is upset as a whole; then the left end of the

blank is drawn and shaped to form an intermediate blank; finally,

the intermediate blank is formed by isothermal forging. The method

can effectively realize the forging of 2024 aluminum matrix

composite splint forgings, and improve the forming quality of 2024

aluminum matrix composite splint forgings. This method is used for

isothermal forging of 2024 aluminum matrix composite plywood

forgings.

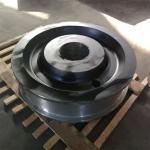

OEM Aluminum Alloy Wheels , T6 Powder Coating Forging Alloy Wheels ISO Certificate An aluminum alloy forging heating and heat-preserving die base is adopted, which includes: a temperature control system and two die bases that cooperate with each other to forge aluminum alloys. The two die bases include an upper die base and a lower die base; the temperature control system includes a heating rod, The thermocouple and the temperature control component, the heating rod and the thermocouple are respectively connected with the temperature control component; the two mold bases have a mold cavity for installing the mold on one side close to each other, and the mold base is arranged around the mold cavity with a heating rod for installing the heating rod. rod mounting holes; the mold base is provided with a thermocouple mounting hole for installing thermocouples; the contact between the upper mold base and the lower mold base is provided with a guiding structure, and the guiding structure includes an upper mold guide plate and a lower mold guide plate; the upper mold guide plate The guide plate of the upper die and the guide plate of the lower die are arranged opposite to each other along the direction perpendicular to the direction of mold clamping and parting, and are in clearance fit. The invention realizes that the aluminum alloy forging can be forged at a relatively stable heating temperature, ensures its forging quality, and overcomes the problem of guide jamming at the same time.

Extra Product Description of OEM Aluminum Alloy Wheels , T6 Powder Coating Forging Alloy Wheels ISO Certificate

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: OEM Aluminum Alloy Wheels T6 Aluminum Alloy Wheels Forging Alloy Wheels ISO | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

T6 Material Aluminum Alloy Wheels ODM For Light Load Rail Cars |

|

Aluminium Forged And Cast Wheels T6 Heat Treatment RoHS Certificate |

|

Kingrail Aluminum Alloy Wheels GT 0010 Castings Processing For Railway Train |

|

Heat Treatment Forged Aluminum Alloy Wheels T6 Material 0.01mm Tolerance ODM |

|

Heat Treatment Wheels Aluminum Alloy T6 6061 6082 Material ODM |

|

0.005mm Tolerance Forged Polished Aluminum Wheels For Light Car ODM |