railcar and locomotive tough longer life wheel AAR standard reliable rail wheels

|

|

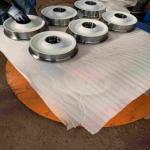

Detailed specification of railcar and locomotive tough longer life wheel AAR standard reliable rail wheels

Front View of railcar and locomotive tough longer life wheel AAR standard reliable rail wheels : Almost all train wheels have a curved projection, a flange, on one side to keep the wheels, and hence the train, running on the rails when the limits or tests of alignment are reached.

Side View of Customized OEM High Wear Resistant Carbon Steel Rail Steel Casting Tractor/Train/Rail/Railway Wheels: The running surface of most is concave, serving as the primary means of keeping the train's motion aligned with the track while in others it is flat such that the flanges are essential to keep the train on the rail track.

Railway train hub advantages: In the heavy haul industry,we have many comprehensive product lines . Whatever your requirements, our Kingrail can deliver the highest quality, most reliable rail wheels for the long haul accordingly.

Wheels tough enough ,72% longer wheel life . lower freight car operating expenses, less time for wheel maintenance to 72% reduction in wheel-set removals translates into. enhanced “fluidity of the service.” Made from a patented material that provides increased resistance to thermal degradation, our various wheel can take the heat at higher temperatures. Available wheel in various diameters for rail -road vehicle and even locomotives.

We have a wide range of forging applications, which can be used in the automotive industry, offshore platforms, parts processing, medical equipment, etc., such as:Military forgings, such as gun barrels, doors, breech brackets and tow rings, etc.Forging machinery and equipment, such as hammer head, hammer rod, hydraulic press column, cylinder block, axle press support and cylinder block, etc.Modular forgings are mainly forging dies for hot die forging hammers.Forgings for hydro-generators, such as main shaft and intermediate shaft, etc.

What are the energy-saving measures for heat treatment in forging plants? The main energy-saving measures for heat treatment in forging plants are to improve heat treatment process, tap heat treatment potential, reasonably shorten production cycle, reduce energy consumption, etc. to save energy, adopt advanced heat treatment equipment with low energy consumption, continuous Production, formulate a reasonable heat treatment process, do a good job in equipment maintenance, etc. Among many energy-saving means, process optimization is one of the effective means to achieve energy-saving and efficiency-enhancing without investing a lot of money.

Energy saving and efficiency enhancement is an important part of the optimization of the heat treatment process of the forging plant, and it is also one of the effective means of energy saving and consumption reduction in the forging plant. Production cycle, reduce energy consumption to achieve economic benefits.

Heat treatment in a forging factory is to heat the forging to a certain temperature, keep it for a period of time, and then adopt different cooling rates to obtain different microstructures. The heat treatment only changes the internal structure of the forging, not the shape of the forging. The method of heat treatment to save energy and increase efficiency is to shorten the production cycle and save energy and reduce consumption by changing parameters such as heating temperature, holding time, and cooling method on the premise of ensuring internal performance. Forging as a traditional industry, forging forging plant is a major energy consumer, mainly reflected in the consumption of electric energy. In the field of forging product manufacturing, electric energy saving is an intuitive energy-saving direction. Energy saving can be achieved through different measures, such as adopting advanced heat treatment equipment with low energy consumption, continuous production, formulating reasonable heat treatment processes, and maintaining equipment well. Among many energy-saving means, process optimization is one of the effective means to achieve energy-saving and efficiency-enhancing without investing a lot of money.

Package of Customized OEM High Wear Resistant Carbon Steel Rail Steel Casting Tractor/Train/Rail/Railway Wheels:Wheels are packed by iron pallets with rings. Due to this complex wheel,rail contact condition, the flange and the thread are with distinct wear regions.a variety of factors cause wear rates in these two parts. such as the vehicle design track curvature, cant deficiency, etc. the status of the contacting surfaces and the mechanical properties of wheel and rail materials. Rail steel wheel

Customized OEM High Wear Resistant Carbon Steel Rail Steel Casting Tractor/Train/Rail/Railway Wheels mainly used for RRV, Road-rail dual-use vehicles refer to special vehicles that can run on railway tracks as well as on general roads and even in the field. also called RRV. It was mainly used in the military in the early days. Hyundai mainly undertakes emergency tasks such as maintenance and rescue of railway lines and along the lines. Road-rail dual-use vehicles are required to be able to switch between roads and railways quickly and easily. It is usually realized by the hydraulic lane-changing slewing device on the chassis and the railway traveling guide wheel device that can be raised and lowered at any time. With the guide wheel device, the general rubber tire wheels can drive straight along the rail. Because this kind of vehicle requires a certain traction and carrying capacity, it can play a unique role in the event that the railway line is interrupted or blocked due to a disaster. Dedicated road-rail vehicles include: electric traction section catenary repair vehicles, excavators used for mountain railway repairs, emergency tractors, generator vehicles, fire trucks, fast bridge vehicles, etc.

Strength of Customized OEM High Wear Resistant Carbon Steel Rail Steel Casting Tractor/Train/Rail/Railway Wheels: 1. Forging production, longer lifespan, for smaller quantity, free forging, for big quantity, precision forging with mould 2. Diameter: 0-1450mm, 6",8",10",12",14",16",20",24",28",30",34",36",40",42",etc 3.100% inspection before delivery

Usage of Customized OEM High Wear Resistant Carbon Steel Rail Steel Casting Tractor/Train/Rail/Railway Wheels: Train, railcars, light rail, street car, metro, freight car, railway wagon for mining, rail trucks, ballast rail cars, Hy-rail hirail cars, etc

The Production Railway Wheels Process 1. Wheels Steel Melting 2. Round Billet Sawing Cutting 3. Heating 4. Phosphorus 5. Stamping Forming 6. Rolling 7. Bending Punch 8. Hot Stamping 9. Laser Measurement 10. Drop Stack 11. Roughing 12.Hardening 13.Tempering 14. Sampling 15. Pre-processing 16. Finishing 16. The Cold Print 17. Static Equilibrium 18. The Cold Print 19. Hardness Testing 20. Ultrasonic Testing 21. Magnetic Particle Testing 22. Shot Peening 23. Painting Packaging Main Testing and Inspection Device

Our Equipments:

Services we can provide:

3. Fast , Convinient Services with High quality products but competitive price.

4. Complete quality inspection procedure to every batch of shipment before delivery.

5. After-service can be warranty last to 3 years of any questions from our customers.

Our aim is to serve customers by providing the the most optimized solution according to the needs of production and meet the satisfaction.

Railway parts products we can provide:

1. The company is in a leading position in the industry and has

obtained SGS-ISO9001: 2008 quality system certification and CRCC

certification. Quality is guaranteed.

4. We are a near sea port city ,We can provide you with faster shipping services.

6.100% inspection before shipment from factory.

|

|

Customized Design Railway Suspension System In Passenger Cars |

|

Custom Forged Alloy Wheels Experience Unmatched Style and Performance |

|

Kingrail Steel Rail Wheels For Open Top Cart Hay Top Notch Performance And Reliability |

|

Easy Maneuverability Reinforced Rail Track Trolley For Heavy Industrial Loads Standard Track Gauge 1435 Mm |

|

Manufacturing Process Heat Treatment Rail Wheels And Axles EN 13261 Europe Standards |

|

Round Vehicle Wheels Forged Alloy Steel For Ultimate Corrosion Protection In Black Or Silver |