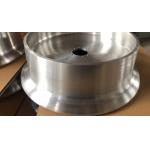

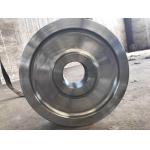

T6 Material Aluminum Alloy Wheels ODM For Light Load Rail Cars

|

|

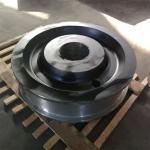

T6 Material Aluminum Alloy Wheels ODM For Light Load Rail Cars

Forged Al alloy T6 wheels for light load rail cars customized production is a lightweight forged aluminum alloy wheel, which is composed of an outer wheel lip, an inner wheel rim hump, a rim, an outer wheel rim hump, an inner wheel lip, a wheel spoke, a flange and a weight reduction groove, and is characterized in that: the outer wheel lip , The inner rim hump, the rim, the outer rim hump and the inner wheel lip are connected end to end in turn; one end of the spoke is connected to the flange, and the other end is connected to the inner wheel lip to form the wheel surface; the weight reduction groove is located in the back cavity of the wheel One side and the inside of the outer rim hump. The aluminum alloy wheel structure of the utility model has the advantages that: compared with the modified front wheel, the aluminum alloy wheel structure has the advantages of light weight after molding, excellent performance test, material saving, good environmental protection and superior performance. Strength of Forged Al alloy T6 wheels for light load rail cars customized production The difference between forged aluminum alloy wheels and other wheels and the supporting situation of forged aluminum alloys in the market. PART ONE Casting Process VS Forging craft Cast aluminum alloy wheels are made by casting molten aluminum water in a sand mold, and then machining (deburring, trimming, polishing) after cooling and forming. Forging is to use a steel mold, place a heated and softened aluminum block in it, shape it by forging, and then machine it after cooling. Casting workpieces are prone to porosity, looseness, slag

inclusion, and coarse grains. During the forging process, due to

the continuous forging and pressing of the aluminum block, after

forming, its molecular structure will become very tight, and the

grains will be finer and more uniform. Forged aluminum alloy wheels

have better strength and can withstand higher pressures, so under

the same size and strength, forged wheels are also lighter than

cast wheels.

Forged aluminum alloy wheels are made of high-strength aluminum

alloy materials. After forging and heat treatment, under the

conditions of the same specifications and the same bearing capacity carbon emissions reduction

2. Good heat dissipation ➡ Extend wheel life Service life of brake pads and tires Effectively control the rapid increase in tire pressure Guaranteed driving safety 3. High dimensional accuracy ➡ Good dynamic balance performance Processed by high-precision CNC turning center During the machining process, one clamping completes the turning of the mounting surface and the contour surface to ensure the coaxiality of the mounting hole and the tire mounting surface It can effectively reduce the jitter caused by high-speed driving and improve the comfort of the whole vehicle

4. Effectively reduce the wear of the wheel ➡ prolong the service

life of the wheel good dimensional accuracy good runout error Good dynamic balance performance Reduce wheel rotation resistance Reduce the friction between the tire and the ground

5. Safe, no fire hazard When the wheel fails or other reasons cause friction between the wheel and the body or both wheels, the aluminum alloy material does not produce sparks. To avoid accidents caused by sparks of oil burning or even vehicle combustion, especially in natural gas transport vehicles and oil tankers, in addition to the use of aluminum alloy wheels, a large part of the entire vehicle adopts an all-aluminum alloy structure. 6. Good corrosion resistance Aluminum alloy wheels The nature of aluminum is lively and it is easy to react with oxygen to form a dense aluminum oxide layer on the surface. ➡Alumina is very stable and not easy to be corroded ➡Alumina layer will act as a protective layer Prevents the aluminum inside from further reacting or corroding steel wheel After the paint peels off, the steel immediately reacts with oxygen, and the rust layer formed after the steel is oxidized is very loose. ➡It will increase moisture absorption and water absorption to accelerate the internal oxidation rate

7, beautiful and generous

Aluminum is called "the metal that never dies". Because of the dense oxide protective film on the surface of aluminum, it is extremely resistant to corrosion and will not rust. Main Production Equipment List

In theory, it can be fully recycled for recycling, and the quality and performance of recycled aluminum and primary aluminum are no different. Aluminum alloy wheels are green metal products that save energy and

reduce emissions. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: T6 Aluminum Alloy Wheels ODM Aluminum Alloy Wheels |

|

T6 Material Aluminum Alloy Wheels ODM For Light Load Rail Cars |

|

Aluminium Forged And Cast Wheels T6 Heat Treatment RoHS Certificate |

|

Kingrail Aluminum Alloy Wheels GT 0010 Castings Processing For Railway Train |

|

Heat Treatment Forged Aluminum Alloy Wheels T6 Material 0.01mm Tolerance ODM |

|

Heat Treatment Wheels Aluminum Alloy T6 6061 6082 Material ODM |

|

0.005mm Tolerance Forged Polished Aluminum Wheels For Light Car ODM |