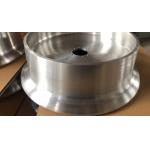

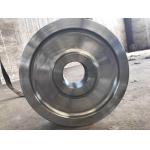

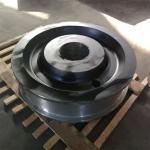

CNC Machining Aluminum Alloy Wheels Forging AISI GB Standard

|

|

CNC Machining Aluminum Alloy Wheels Forging AISI GB Standard

Characteristics of CNC Machining Aluminum Alloy Wheels Forging AISI GB Standard The processing requirements for this product are very high. The temperature of the machining workshop must be kept at a constant temperature.This is hot sale in Germany, UK, US, etc there are size of 21" and 26" now.and at the same time develop and produce other train forged parts for them.

Repair process for spraying defects of aluminum alloy fine wheels.

In the process of returning defective products to the car, collapse

defects are prone to occur, and the boundary lines are not neat and

smooth, which affects the subsequent process steps and leads to

product defects. The general treatment method is to strip paint off

the line and re-spray. The repair pass rate is low, causing

material waste, affecting production progress, increasing costs,

and reducing the production efficiency of enterprises. The

repairing process of the invention is characterized in that, for

the fine wheel with slight disintegration defect, the surface

coating of the fine wheel can meet the appearance requirements of

the product by directly re-spraying the bright powder, and then

grinding and polishing after curing. It solves the problem of new

defects caused by the return of fine wheels, and greatly improves

the coating efficiency of fine wheels. Compared with the original

process of treating defects by stripping paint, it greatly reduces

the production cost of wheel painting and the rate of wheel

disintegration. . The aluminum alloy wheel forging method includes the following steps: S10, heating the blank, and heating the blank to a preset forging temperature; S20, placing the heated blank at the first forging station of the lower die assembly, The upper die and the lower die of the first forging station are aligned and moved downward, and the upper die, the Huff die ring and the lower die cooperate with each other to realize the first forging process of the blank, and obtain the first forging shaped hub; S30 , The lower die assembly moves the second forging station to the lower part of the upper die, the upper die and the Huff die ring go down and cooperate with the lower die, and the second forging process is performed on the first forged hub to obtain the second forged hub The aluminum bar forging process includes the following steps: the aluminum material is put into a heating furnace, the furnace temperature is heated to melting, the aluminum bar is melted, the molten aluminum liquid is taken out from the furnace, and poured into a mold for pressing, with aluminum After the liquid is cooled, the aluminum liquid becomes an aluminum block, so that the cooled aluminum block is taken out from the mold, and then the aluminum block is forged. The forging is performed by heating and beating. , Repeatedly, remove the edge of the beaten aluminum block and repair the shape The aluminum alloy wheel forging heating device includes a base, the top of the base is fixedly installed with mounting brackets, the top of the base is fixedly installed with a feeding table located between the two mounting brackets, and the top of the base is fixedly installed with The forging table is located on the right side of the feeding table, the top of the base is fixedly installed with the unloading table located on the right side of the forging table, and the mounting frame on the rear side is provided with an installation groove, and the electric screw rod is fixedly installed in the installation groove. , the output shaft of the electric screw is threadedly connected with a screw nut. The automobile aluminum alloy wheel hub forging heating device solves the problem that the existing automobile wheel hub heating device is inconvenient to use, and the workload of the staff is large, which is not conducive to the large-scale production of automobile wheel hubs. Odor gas, which easily affects the respiratory health of surrounding staff For the wheels production, we use A multi-station forging device for an aluminum alloy wheel hub, comprising: an upper die assembly and a lower die assembly, the lower die assembly is provided with a plurality of forging stations, and the upper die assembly and the lower die assembly have a plurality of forging stations. The forging stations cooperate to complete a plurality of forging processes; wherein, the upper die assembly includes: an upper die plate, an upper die seat is fixedly connected below the upper die plate; an upper die is arranged on the lower surface of the upper die seat; a mold frame, which is arranged under the upper die plate and outside the upper mold seat; a spring seat, which is arranged between the upper mold seat and the mold frame, and a first return spring is arranged in the spring seat; a discharge ring, which is It is arranged on the outside of the upper die seat and connected to the lower surface of the spring seat; a pair of Huff die ring splitting parts are symmetrically arranged on both sides of the lower part of the mold frame, and each of the Huff die ring splitting parts is provided with Hough mode, two Hough modes are combined to form a Hough mold ring, and a cavity is formed between the Hough mold ring and the upper mold With An aluminum alloy small draft forging die, comprising an upper die, a lower die and an ejector device, the upper die is composed of an upper template, the lower die is composed of a concave lower die sleeve and an upper and lower sleeve. The lower die core and the lower backing plate are arranged in the concave lower die sleeve. The forging cavity is provided with a matching combined gasket, the concave lower die sleeve, the lower die core, the lower backing plate and the combined gasket are respectively hollow cylindrical structures, and the ejector is provided through the In the center of the lower mold, the ejecting device is arranged through the center of the lower mold and matched with the lower mold core and the lower backing plate. The utility model provides an aluminum alloy small mold with small process margin, which can be demolded smoothly, and can be smoothly demolded and continued to be produced in the event of a stuck die, which reduces production cost, shortens production and manufacturing cycle, and has good molding effect. Slope forged abrasives.

Extra Product Description of CNC Machining Aluminum Alloy Wheels Forging AISI GB Standard

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Aluminum Alloy Wheels AISI CNC Aluminum Alloy Wheels GB Wheels Aluminum Alloy | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

T6 Material Aluminum Alloy Wheels ODM For Light Load Rail Cars |

|

Aluminium Forged And Cast Wheels T6 Heat Treatment RoHS Certificate |

|

Kingrail Aluminum Alloy Wheels GT 0010 Castings Processing For Railway Train |

|

Heat Treatment Forged Aluminum Alloy Wheels T6 Material 0.01mm Tolerance ODM |

|

Heat Treatment Wheels Aluminum Alloy T6 6061 6082 Material ODM |

|

0.005mm Tolerance Forged Polished Aluminum Wheels For Light Car ODM |