Processing form: processing according to drawings, customized by

customers.

Processing capacity: within 30 tons, within 5 meters of large outer

diameter.

Process types: free forging, model forging, tire die forging and

special forging.

Application areas: large machinery and equipment, lifting

equipment, metallurgy, chemical industry, engineering, marine

industry and other fields.

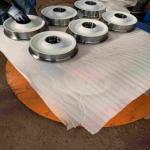

Common materials of crane wheels forged production 42CrMo as

material 380mm diameter with bolt hole

Carbon Steel: A350LF2, A105, Q235, Q355D, A694F52, A516-GR65,

EN10222, P280GH, P245GH, P250GH, JIS S25C, SS400, S20C, 16Mn,

C22.8, Q345B/C/D, 1055, 1045, C50, C45, 10#, 20#, 35#, 45#, 40#,

50#, 60# and other forgings.

Stainless Steel: ASTM, A182, F304/304L, F316/316L, F316H, F310,

F321, JB4728-2000, OCR18Ni10Ti, JB4728-2000, OCR17NI12Mo2, 2205,

2507, 2103, 904L, 254SMD3, 304LN3, 316LN 3cr13, 4cr13, 321, 302,

W1813N, W2014N, W2018N, W2020N, P550, Cr18Mn18N and other

forgings.

Alloy Steel: 42CrMo, A182F1, F5, F9, F11, F91, F92, F22, 12Cr2Mo1,

10Cr9Mo1VNbN (F91), 10Cr9MoW2VNbBN (F92), JB4726-2000, 15CrMo,

JB4726-2000, 12CrMoV, 35Cr30, 4140, 4340 a -8Mo, 15-5PH, AerMet100

and other forgings.

Special steel: ASTM182F51, S31803, A182F309, Monel N04400, A182F310

and other forgings.

Tool and die steel: P20718, NAK80, S50C, 4Cr13, 3Cr17Mo, 5CrNiMo,

5CrMnMo, 4Cr2NiMoV, S7, H10, H11, H12, H13, H13 MOD, SUP H13,

D2, A2, A6, A8, O1, O2, 9Cr2Mo, MC3, MC5, 7Cr3, 21CrMo10, 1Cr17Ni2,

310 and other forgings

Heat-resistant steel: 12CrlMoVG, P11, P22, P91, P92, F92,

InconeI740H, CCA617, Sanicro25 alloy and other forgings

Bearing steel: G20CrNiMoA, G2CrNi2MoA, G20Cr2Ni4, GCr15, GCr15SiMn,

GCr15SiMo, GCr18Mo, M50, M50NiL, CSS-F42L, Cronidur30 and other

forgings

Gear steel: 42CrMo, 20CrNi2Mo, 34CrNi3Mo, 40CrNiMo, 20CrMnMo,

35CrMo, 18CrNiMo7-6 and other forgings

Packaging: Plastic, plywood boxes or pallets.