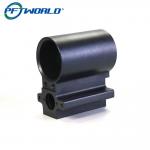

OEM ODM Aluminum Turned And Milled Parts Precision CNC Machined Parts

|

|

OEM ODM CNC Machined Aluminum Turned Milled Parts Factory Precision

Quick details: 1. Keyword: CNC Aluminum Parts 2. Process: CNC Turned Milled Service 3. Color: Customized Colors 5. Application: Wide Range Of Applications 6. Drawing Format: 2D/(PDF/CAD)3D(IGES/STEP) 7. Equipment: CNC Machining Centers 8. Lead time: 1-2 weeks

Details:

CNC Machining Capabilities

We have a skilled engineering team with expertise in ISO9001, ISO13485, AS9000, and IATF16949 quality systems, along with ERP/MES systems, enabling us to handle one-time prototype and mass production. Our digital factory allows real-time tracking of project progress. We also utilize quality inspection equipment such as CMM and 2D measuring instruments to ensure stringent quality control.

Why Choose Us for Custom CNC Machining?

CNC Machining Applications

Certainly! Here are examples to illustrate each of the listed items:

FAQ: A: Yes, we will not publish your design to a third party unless

your permission is obtained. We can sign the NDA before you send

the drawings.

|

||||||||||||||

| Product Tags: Aluminum Turned And Milled Parts Precision CNC Machined Parts |

|

Aluminum 7075 CNC Machining Parts Milling Turning 50um Teflon Coating 30um |

|

Bevel gear CNC machining aluminum parts |

|

Black Anodized Machined Aluminum Parts Milling Custom High Tolerance |

|

Custom Milling 6061 T6 Cnc Machined Aluminum Parts Back Adjuster |

|

Anodized 6063 Aluminum Cnc Machining Parts Custom |

|

6082 Cnc Machined Aluminum Parts Precision Milling Service Custom |