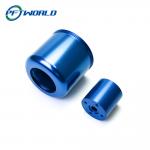

Precision Turned CNC Machined Aluminum Parts

|

|

In the world of manufacturing, precision is paramount. Whether you're in aerospace, automotive, electronics, or medical industries, the demand for high-quality, high-performance parts is ever-increasing. When it comes to achieving superior accuracy and consistency, precision turned CNC machined aluminum parts stand at the forefront. CNC (Computer Numerical Control) machining combined with the lightweight and durable properties of aluminum makes this a powerhouse solution for manufacturers who require complex, tight-tolerance parts with excellent performance characteristics.

Why Choose Precision Turned CNC Machined Aluminum Parts?

1.Exceptional Precision and Accuracy CNC machines are known for their high degree of precision, capable of achieving tight tolerances that manual machining simply cannot match. This is especially important in industries where parts must meet exacting specifications. Whether it’s for intricate aerospace components, precise medical devices, or custom automotive parts, CNC turning ensures that every detail is replicated with utmost accuracy.

2.Superior Material Properties of Aluminum Aluminum is renowned for its combination of lightweight, strength, and corrosion resistance, making it a perfect material for CNC machining. It offers excellent machinability, which results in smoother finishes and faster production times compared to other materials. Furthermore, aluminum's ability to resist oxidation and wear ensures that the parts maintain their performance and appearance, even in harsh environments.

3.Customization and Design Flexibility One of the key benefits of CNC turning is the flexibility it offers in design. With CNC technology, manufacturers can easily produce parts with a wide range of geometries, from simple cylindrical shapes to complex, multi-featured components. Our CNC machines are capable of handling intricate designs that require multiple turning and cutting operations, allowing for custom parts that suit the unique needs of your project.

4.Cost-Effective, High-Volume Production While CNC machining may seem like a significant initial investment, the long-term benefits are undeniable. CNC turning provides rapid and efficient production, particularly for high-volume orders. The automated nature of the process minimizes human error, reduces waste, and ensures consistent quality across all parts, resulting in cost-effective manufacturing, especially for large production runs.

5.Excellent Surface Finish and Tight Tolerances Precision turned aluminum parts benefit from superior surface finishes that enhance both their aesthetic appeal and functionality. A smooth surface finish is particularly important in applications like aerospace, medical devices, and electronics, where part performance and user experience are critical. CNC turning also ensures tight tolerances, which is a necessity for industries that require parts to fit together seamlessly.

Key Industries for Precision Turned CNC Machined Aluminum Parts

2. Automotive

3. Electronics

allows for the production of parts with exact specifications, ensuring that the electronics function optimally within their enclosures.

4. Medical Devices

5. Industrial Equipment

Industrial machinery often requires parts that can endure heavy-duty conditions. CNC turned aluminum parts offer strength, resistance to corrosion, and the ability to withstand wear and tear. Components such as gears, axles, and valves benefit from the precision and durability that CNC turning provides, ensuring smooth and reliable operation in demanding environments.

Conclusion

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

| Product Tags: Precision Turned CNC Machined Aluminum Parts Bushing CNC Machined Aluminum Parts |