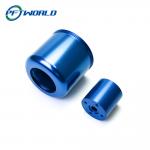

Custom Precision Aluminum CNC Milling Parts Services

|

|

Product Description:

In today’s fast-paced manufacturing environment, the demand for custom precision aluminum CNC milling parts services is at an all-time high. Whether you're in the aerospace, automotive, medical, or electronics industries, the need for components that are not only functional but also precise and durable is essential. CNC milling (Computer Numerical Control milling) offers a level of precision that traditional machining methods cannot match, and when applied to aluminum—a material known for its versatility, strength-to-weight ratio, and ease of machining—it becomes the ideal choice for creating high-performance parts.

What Are Custom Precision Aluminum CNC Milling Parts Services?Custom precision aluminum CNC milling parts services refer to the process of creating bespoke aluminum parts using advanced CNC milling technology. CNC milling uses computer-controlled machines to remove material from a block of aluminum, precisely shaping it into the desired part with exact tolerances and intricate details. Unlike traditional machining methods, CNC milling allows for high precision, repeatability, and flexibility. With custom precision aluminum CNC milling, parts can be made to meet exact design specifications, ensuring high-quality, durable components that fit perfectly within the intended system or assembly. These services are ideal for creating both prototype and production-grade parts across a range of industries.

The Key Benefits of Custom Precision CNC Milling for Aluminum Parts:1. Unmatched Precision and AccuracyOne of the main advantages of CNC milling is its ability to achieve incredibly tight tolerances. With custom precision aluminum CNC milling, manufacturers can create parts with tolerances as tight as ±0.001 inches or even finer, depending on the specific requirements. This level of precision ensures that parts fit together perfectly and function as intended, making CNC milling the go-to choice for industries where accuracy is critical. 2. Complex Geometries and Custom DesignsCNC milling allows for the creation of parts with complex geometries that would be difficult or impossible to achieve with traditional machining. From intricate curves and 3D shapes to precise holes, slots, and threads, custom aluminum CNC milling parts can be designed to meet the specific needs of each project. Whether you need a custom bracket, gear, housing, or prototype, CNC milling offers the flexibility to create a wide range of part designs with ease. 3. Efficiency and Cost-EffectivenessWhile CNC milling may have a higher upfront cost than traditional methods, it is a cost-effective option in the long run due to its efficiency and reduced labor costs. Once the design is programmed into the CNC machine, the process can run automatically, minimizing the need for manual intervention and reducing the risk of errors. CNC milling also minimizes material waste, as the material is precisely removed from the block, leading to cost savings. 4. Quick Turnaround TimeWith custom precision aluminum CNC milling parts services, companies can significantly reduce lead times. CNC machines can operate 24/7, which means manufacturers can quickly produce parts, from prototypes to production runs. This makes CNC milling an ideal solution for industries that require fast delivery times without compromising on quality. 5. Superior Surface FinishAnother advantage of CNC milling is the ability to achieve superior surface finishes. Aluminum has an excellent surface quality that can be enhanced further during the milling process, creating smooth, polished surfaces that are free from imperfections. This makes aluminum parts not only highly functional but also aesthetically appealing, ideal for consumer-facing products like electronics, automotive components, and decorative items.

Industries That Benefit from Custom Precision Aluminum CNC Milling Parts Services:

ConclusionCustom precision aluminum CNC milling parts services are an indispensable solution for manufacturers seeking high-quality, durable, and precisely machined components. Whether you need prototypes or large production runs, CNC milling offers unmatched precision, speed, and cost-effectiveness. By partnering with a factory that specializes in CNC milling, you can access tailored solutions that optimize performance, reduce lead times, and improve overall production efficiency.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

| Product Tags: Anodized Black Metal Spare Parts CNC Milling Metal Spare Parts |