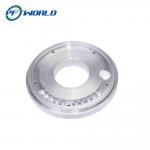

CNC Turning and Milling Parts Stainless Steel Manufacturing with Gold Hexagonal Design

|

The Advantages of CNC Turning and Milling Key Benefits: |

| Product range | CNC Injection Molding Shell Frame Parts, Plastic Injection Parts |

| Processing Craft | Mold fabrication, Injection, etc; |

| Material | ABS, BMC, SMC, AS, PP, PPS, PC, PE, POM, PMMA, PS, HDPE, TPE, TPU, etc |

| Surface finish | Polishing finish, Texture Finish, Glossy Finish, Painting, Slik print, Rubber Painting, etc |

| Color | RAL/PANTONE color |

| Size | according to the drawing |

| Mold Standard | DME,LKM,FUTA,HASCO etc. |

| Advantages | Competitive price & Fast Delivery & Good quality |

| Mould Base | as per the customer's requirement |

| Delivery time | 10-15 days after placing an order |

| Tolerance | 0.01~0.1mm; |

| File Format | Solidworks, Pro/Engineer, Auto CAD, PDF, JPG |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC, FQC, QA |

| Application | All kinds of plastic injection parts are being used in a variety of industrial applications. |

| Service | Warm and quick response service provided by the professional |

FAQ:

Q:What is CNC turning and milling?

A:CNC (Computer Numerical Control) turning and milling are

machining processes that use computer-controlled machines to shape

materials, such as stainless steel, into precise parts. Turning

involves rotating the material against a cutting tool, while

milling uses a rotating tool to remove material from a stationary

workpiece.

Q:What types of stainless steel are typically used?

A:Common grades include:

- 304: General-purpose, excellent corrosion resistance.

- 316: Better corrosion resistance, particularly in marine environments.

- 440C: High hardness, used for cutlery and tooling.

Q:What is the typical lead time for CNC machining stainless steel parts?

A:Lead times vary based on complexity and volume but typically range from a few days to several weeks. Rapid prototyping can often be done in shorter time frames.

Q:How do you choose the right machining process?

A:Selection depends on factors such as part complexity, material

properties, required tolerances, and production volume. A

combination of turning and milling may be used for intricate

designs.

Q:Can you provide design recommendations for CNC machining

stainless steel?

- Avoid sharp corners: Use fillets to reduce stress concentrations.

- Design for manufacturability: Simplify shapes where possible.

- Specify tolerances carefully: Only call out tight tolerances where necessary.

Q:How do you ensure quality in CNC machining?

A: Quality control measures may include:

- In-process inspections.

- Final inspection using precision measuring tools.

- Material certifications and compliance with industry standards.

Q: What industries benefit from CNC machined stainless steel parts?

- Aerospace

- Automotive

- Medical devices

- Food and beverage

- Oil and gas

|

Small CNC Turning Precision Parts |

|

Custom CNC Turning Lathe Parts with Black Surface Treatment and ODM Service High Precision ±0.005mm Tolerance |

|

Zinc Plated CNC Turning Parts Long Lasting with CNC Drilling / Tapping Surface Protection |

|

Custom Metal Fabrication CNC Turning Spare Parts 3 4 5 6 Axis CNC Machining Service |

|

OEM CNC Turning Materials for High Precision Sensor Parts in Mechanical Industry |

|

CNC Turning Parts Aluminum Copper Stainless Steel Precision Machining Components ISO Certified |