|

In the world of modern manufacturing, the demand for high-performance, durable, and visually appealing components is growing across industries such as aerospace, automotive, electronics, and consumer products. One of the most effective ways to meet these demands is through custom turned aluminum precision CNC machining, coupled with black anodizing. This powerful combination offers exceptional strength, precision, and an aesthetically pleasing finish, making it the ideal solution for producing top-quality components. At the heart of this advanced process lies CNC machining, a method that ensures unparalleled accuracy and repeatability. Paired with the protective and attractive qualities of black anodizing, custom turned aluminum components are ready to withstand the toughest environments while delivering exceptional performance. Here’s why investing in custom turned aluminum precision black anodized CNC machining is the perfect choice for your next project. What is Custom Turned Aluminum Precision CNC Machining?

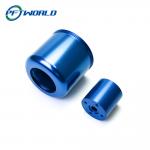

Custom turned aluminum CNC machining is a highly precise manufacturing process where aluminum workpieces are mounted on a CNC lathe, and precision cutting tools are used to shape the material into complex parts. The CNC machine is computer-controlled, ensuring accuracy down to the finest tolerances, allowing manufacturers to produce intricate designs with ease.

Turning refers to the process of rotating the aluminum material while a cutting tool is used to remove material, creating cylindrical shapes, grooves, threads, and other specific features. This method is particularly effective for producing custom parts with symmetrical geometries, such as shafts, bushings, and fittings. What is Black Anodizing?

Black anodizing is an electrochemical process that enhances the surface properties of aluminum. By applying an electrical current to aluminum while immersed in an acid electrolyte solution, the metal's surface undergoes a transformation, resulting in a thicker oxide layer. This layer not only provides additional protection against corrosion but also adds a sleek, black finish that is both aesthetically appealing and highly functional.

Benefits of Black Anodizing: - Enhanced Durability: The anodized layer significantly improves the material's resistance to wear, scratches, and corrosion, making black anodized aluminum parts more durable and long-lasting.

- Aesthetic Appeal: Black anodizing gives aluminum parts a professional, uniform, and matte black finish, making them suitable for applications where appearance matters, such as consumer electronics, automotive parts, and more.

- Improved Insulation: The anodized surface is non-conductive, offering electrical insulation properties, which can be particularly useful in electronic applications.

- Environmentally Friendly: The anodizing process is environmentally friendly, as it uses no harmful chemicals and is a safe method for improving the material properties of aluminum.

Advantages of Custom Turned Aluminum Precision Black Anodized CNC Machining

When combining custom turned aluminum precision machining with black anodizing, manufacturers unlock a host of benefits that make this process indispensable across a range of industries:

1.High Precision and Tight Tolerances

With CNC machining, manufacturers can achieve exact dimensions and tolerances, ensuring that every custom aluminum part fits perfectly within an assembly. The ability to produce components with tight tolerances is essential for high-performance applications like aerospace, medical devices, and electronics. 2.Complex and Customizable Designs

CNC machining allows for the creation of highly intricate designs that would be impossible or cost-prohibitive to achieve using other manufacturing methods. Whether you need parts with detailed grooves, threads, or complex profiles, CNC machining delivers unmatched design flexibility. Additionally, black anodizing does not compromise the part’s custom features, enhancing both form and function. 3.Superior Surface Finish and Protection

The combination of CNC machining and black anodizing produces parts that are not only precisely shaped but also have an attractive, durable finish. The anodized surface is resistant to abrasion, corrosion, and fading, ensuring that your components maintain their appearance and performance over time. 4.Increased Strength and Durability

The anodizing process enhances the aluminum's natural properties, increasing its strength and resistance to damage. This makes custom turned aluminum parts ideal for use in demanding applications where longevity and reliability are critical. 5.Cost-Effective for Both Small and Large Runs

CNC machining offers great flexibility, making it suitable for both small, custom orders and larger, high-volume production runs. The combination of precision machining and anodizing ensures that you can produce parts that meet both quality and cost-efficiency requirements, no matter the order size. Applications of Custom Turned Aluminum Precision Black Anodized CNC Machining

The versatility of custom turned aluminum precision black anodized CNC machining makes it the go-to solution for a wide variety of industries:

- Aerospace: Lightweight, durable, and corrosion-resistant aluminum parts are essential in aerospace, where performance and reliability are crucial. Black anodizing provides additional protection against the harsh environments these components endure.

- Automotive: CNC-machined aluminum components are used extensively in the automotive industry for custom parts like brackets, bushings, and housings. The anodized finish offers protection against the elements while providing an attractive look.

- Electronics: Black anodized aluminum is often used for creating enclosures, housings, and brackets for electronics. The anodized surface ensures that the parts are scratch-resistant and offer electrical insulation, making them ideal for sensitive electronic applications.

- Consumer Products: Whether for custom tooling, parts for outdoor equipment, or luxury goods, the combination of precision machining and black anodizing gives a high-end, sleek finish that appeals to consumers.

- Medical Devices: In the medical field, custom aluminum parts need to meet strict regulatory standards for precision and durability. CNC machining allows for the production of parts with intricate features, while anodizing enhances the parts' strength and resistance to wear.

Conclusion

Custom turned aluminum precision black anodized CNC machining offers the perfect balance of precision, strength, and aesthetics, making it an ideal choice for industries that demand high-performance components. Whether for aerospace, automotive, electronics, or medical applications, this combination of advanced machining techniques and protective anodizing ensures that your parts meet the highest standards of quality, durability, and functionality.

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. | | | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. | | Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | | Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | | Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | | Titanium: Grade F1-F5 | | Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | | | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. | | | ±0.002 ~ ±0.005mm | | | Min Ra 0.1~3.2 | | CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ 1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week. |