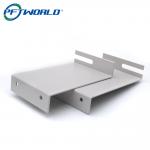

Precision bending parts, sheet metal parts

Quick Details:

1. Keywords: sheet metal parts

2. Process: sheet metal manufacturing

3. Color: silver

4. Origin: Guangdong, China

5. Application: Any

6. Drawing format: 2D/(PDF/CAD) 3D (IGES/STEP)

7. Delivery time: 1-2 weeks

Description:

Bending is an indispensable process in the processing of stainless

steel sheet metal parts. The so-called bending is a stamping

process, which uses pressure to force the material to deform and

form a certain angle and curvature shape. Common bending includes

V-shaped bending, Z-shaped bending and equal bending pressure. The

most important thing for bending is to pay attention to the

following points: bending height, bending radius, bending direction

and bending gap. This page is a customized Z-bend product in the

past. Stainless steel is difficult to bend, usually used to bend

stainless steel 301 and 304.

301 stainless steel can be deformed better in the bending process

due to its good ductility. 304 stainless steel is the most common

stainless steel

Processing process of precision hardware accessories:

One is to open materials according to production needs. After

opening, some small parts can be produced by punching machine and

then processed by gong cutting or CNC. This is a lot in the

production of eyewear parts and auto parts. As for containers,

after blanking and punching, they are welded, sanded, sprayed with

oil, and then assembled with accessories. For small parts, there

are many polished surfaces to be cleaned, plated or sprayed. Then

welding or screwing, assembling, packaging and shipping.

Specification:

| Material | Stainless Steel |

| Application | Any |

| Color | blue |

| Package | Carton Box |

| Surface treatment | Testure/Sand/MT/YS/SPI/VDI |

| Drawing format | 2D/(PDF/CAD),3D(IGES/STEP) |

| Certificates | ISO9001:2015/ISO13485:2016 |

| Lead time | 1-2 weeks |

FAQ:

Q1. Are you a manufacturer or a trading company?

We are factories.

Q2. How to get a quotation?

A2. Please provide 2D and 3D drawings, recommended quantity,

surface treatment, finish and special requirements; We will quote

within 1 or 2 days after receiving the details.

Q3. If I don't have drawings, how can I get a quotation?

A3. You can send us the samples, and we will scan and draw 2D and

3D drawings for your inspection.

Q4. How do you guarantee quality?

A4. Our production will strictly comply with the drawing

requirements. We provide detailed photos for your confirmation

before shipment. Any quality problems may require rework of parts

at no additional cost.

Q5: Will it be safe after we get our drawings?

A5. Yes, we can sign a confidentiality agreement before receiving

the drawings.