Custom Plastic Molded Components Precision Connector Mold Parts

|

|

Description:

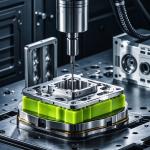

Custom plastic molding involves creating parts by injecting molten plastic into a specially designed mold. This process allows for the production of intricate shapes and designs that meet specific requirements. Customization is key, as manufacturers can tailor the size, shape, and material properties to suit their particular needs.

Benefits of Custom Plastic Molded Components:

Applications of Precision Connector Mold Parts

Specification:

Conclusion:

Investing in custom plastic molded components and precision connector mold parts can significantly enhance your production capabilities and product quality. By collaborating with a skilled manufacturer, you can ensure that your components meet the highest standards of performance and reliability.

FAQ:Q:What are custom plastic molded components?Answer: Custom plastic molded components are parts created through the injection molding process, tailored to specific designs and requirements for various applications across different industries. Q:What are precision connector mold parts?Answer: Precision connector mold parts are specifically designed components used in electrical connections, ensuring secure and reliable connections in devices like electronics and automotive systems.

Q:What are the benefits of using custom plastic molding?Answer: Custom plastic molding offers high precision, design flexibility, material versatility, cost-effectiveness, and scalability, making it ideal for producing intricate components in bulk. Q:What materials can be used for plastic molding?Answer: A wide range of materials can be used, including ABS, polycarbonate, nylon, and polypropylene, each offering different mechanical and thermal properties suitable for various applications.

Q:How are precision connector mold parts made?Answer: These parts are made by injecting molten plastic into a custom mold designed specifically for the connector shape, allowing for high precision and tight tolerances. Q:What industries commonly use custom plastic molded components?Answer: Industries such as electronics, automotive, medical devices, and consumer goods frequently utilize custom plastic molded components for their products. Q:What is the typical lead time for producing custom molded parts?Answer: Lead times can vary based on design complexity and order volume, but efficient manufacturing processes typically allow for quicker turnaround times. It’s best to consult directly with your supplier for specific timelines. Q:Can I get custom designs for my specific needs?Answer: Yes! Custom plastic molded components can be tailored to meet your specific design requirements, ensuring that they fit seamlessly into your applications. Q:How do you ensure the quality of molded components?Answer: Quality is ensured through rigorous testing and quality control processes at every stage of production, including design validation, material selection, and final inspection. |

|

High Durability Injection Molding Parts With Grinding / EDM / QC Processing |

|

Custom injection mold parts |

|

Customized Injection Molded Plastic Parts For Various Public Area Applications OEM |

|

Durability Public Area Injection Molded Plastic Parts For Airports And Hotels |

|

Processing plastic injection mold CNC parts |

|

CNC machining custom size injection plastic mold parts |