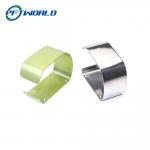

Customized precision bending silver box accessories

|

|

What Are Customized Precision Bending Silver Box Accessories?

Precision bending is a manufacturing process where metal sheets, such as silver, are carefully shaped using advanced machinery to achieve the desired angles, curves, and dimensions. Our service specializes in customized precision bending, ensuring that each part fits your unique specifications with accuracy and efficiency. When it comes to silver box accessories, whether for jewelry boxes, electronic enclosures, or high-end decorative pieces, our precision bending ensures that your components stand out in terms of both form and function.

Applications of Customized Precision Bending Silver Box Accessories

1.Jewelry Boxes

Precision-bent silver accessories for luxurious and stylish boxes, ensuring that every detail is carefully crafted.

2.Electronics Enclosures

Custom silver components used in high-end electronic device housings, providing both functionality and elegance.

3.Decorative Accessories

Intricately designed silver accents and fittings for home décor items, enhancing their visual appeal.

4.High-End Packaging

Precision-bent silver components for custom packaging solutions, ensuring that your products are presented in a unique and sophisticated manner.

Benefits of Our Customized Precision Bending Service

We utilize state-of-the-art CNC bending machines to achieve superior results with minimal waste, ensuring precise and repeatable parts.

2.Experienced Craftsmanship

Our team of skilled technicians brings years of expertise to each project, ensuring that your silver box accessories are manufactured with the highest standards of quality.

3.Flexible Production Capacity

Whether you need a small batch or large-scale production, our flexible manufacturing capabilities can accommodate your needs.

4.Comprehensive Finishing Options

Enhance your parts with finishes like polishing, electroplating, or oxidizing, adding a beautiful and durable surface to your silver box accessories.

5.Global Reach

We provide shipping worldwide, ensuring that no matter where you are, your custom parts arrive on time and in perfect condition.

Our Process for Customized Precision Bending

1.Initial Consultation & Design Review

Share your design files or ideas with us, and our engineers will review the specifications to ensure manufacturability and provide expert advice on material selection and design optimization.

2.Material Selection

Choose from a range of silver grades and finishes to achieve the desired appearance and durability for your box accessories.

3.Precision Bending & Shaping

Using advanced CNC bending equipment, we shape the silver to the exact specifications, ensuring perfect angles and dimensions.

4.Surface Finishing

We apply custom finishes to enhance the aesthetics and functionality of your accessories, including polishing and electroplating to create a brilliant, long-lasting appearance.

5.Quality Control & Delivery

Each piece is rigorously inspected to ensure it meets our high standards before being carefully packaged and shipped to your location.

Contact Us for Your Customized Precision Bending Silver Box Accessories

When you need customized precision bending silver box accessories, our service delivers exceptional quality and precision. Let us bring your design ideas to life with our expert craftsmanship and state-of-the-art equipment.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

OEM Sheet Metal Stamping Enclosure Manufacturing |

|

CNC stainless steel spraying surface treatment bracket bending sheet metal parts |

|

Precision bending sheet metal accessories |

|

OEM customized bending parts service |

|

Precision Customized Aluminum Laser Cutting Parts Service |

|

OEM Stainless Steel Bending Sheet Metal Parts Aluminum Powder Coating |