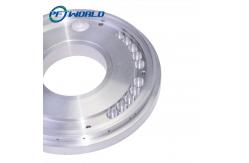

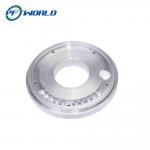

Aluminum CNC Turning Milling Parts Dark Gray Oxidation UV Protection Precision Parts

|

|

Aluminum CNC Turning Milling Parts Dark Gray Oxidation UV Protection Precision Parts Turning Milling Composite Characteristics: 1. The turning and milling compound machine tool perfectly integrates the CNC lathe with the multi-sided machine tool, and has the functions of CNC turning and multi-sided forming chip cutting. It can complete many processes such as turning an outer circle, drilling, cutting, and multi-sided turning at one time. (product concentricity is high, and one machine is multi-purpose). 2. The turning and milling compound machine tool adopts the sand turning process of connecting the bed body and the bed foot, and adopts the roller imported line rail and lead screw, so it has good seismic resistance and strong cutting force. 3. The turning and milling compound machine tool can realize the spindle positioning according to different products and can cut arbitrary polygon processing (it can simultaneously complete irregular shapes such as three, four, five, six, seven, etc.) 4. If the turning and milling compound machine tool does not use the function of turning polygon, it can also be used as a high-precision CNC lathe.

Turning Features: Turning is a method of cutting a workpiece on a lathe using the rotation of the workpiece relative to the tool. Turning is the most basic and common cutting method. Most workpieces with revolving surfaces can be processed by turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads, and rotary forming surfaces. Common lathes can be divided into horizontal lathes, floor lathes, vertical lathes, turret lathes, and profiling lathes, most of which are horizontal lathes. Turning has higher efficiency than grinding, turning often adopts a large cutting depth, and high workpiece speed and its metal resection rate is usually several times that of grinding processing. During vehicle machining, one loading clamp can complete a variety of surface machining, while the grinding requires multiple installations, so the auxiliary time is short and the position accuracy between the machining surfaces is high.

In Which Case You Can Contact:

If you are interested, please feel free to contact me: at sales04@7-swords.com 2. We quote for you 3. Negotiation phase, you can put forward your ideas and

requirements 4. We will arrange production for your order, and follow up on the production progress for you by taking photos, and videos or inviting you to the factory inspection 5. Complete production, 100%QC qualified after shipment 6. You pay the balance and wait to receive the goods FAQ:

|

||||||||||||||

| Product Tags: Aluminum CNC Turning Milling Parts Oxidation CNC Turning Milling Parts | ||||||||||||||

|

Plated Anodizing CNC Turning Milling Parts Stainless Steel Fabrication |

|

Small CNC Turning Precision Parts |

|

CNC Turning Parts Aluminum Copper Stainless Steel Precision Machining Components ISO Certified |

|

Anodized CNC Turning Parts |

|

Oxidizing Aluminum Turning Parts |

|

OEM Brass Metal CNC Turning Parts SUS303 Stainless Steel ISO9001 |