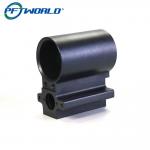

CNC Machined Aluminum Parts High Precision 5 Axis Aluminum CNC Machining Parts

|

|

CNC Machined Aluminum Parts High Precision 5 Axis Aluminum CNC Machining Parts

Turning Milling Composite Characteristics: 1. The turning and milling compound machine tool perfectly integrates the CNC lathe with the multi-sided machine tool, and has the functions of CNC turning and multi-sided forming chip cutting. It can complete many processes such as turning an outer circle, drilling, cutting, and multi-sided turning at one time. (product concentricity is high, and one machine is multi-purpose). 2. The turning and milling compound machine tool adopts the sand turning process of connecting the bed body and the bed foot, and adopts the roller imported line rail and lead screw, so it has good seismic resistance and strong cutting force. 3. The turning and milling compound machine tool can realize the spindle positioning according to different products and can cut arbitrary polygon processing (it can simultaneously complete irregular shapes such as three, four, five, six, seven, etc.) 4. If the turning and milling compound machine tool does not use the function of turning polygon, it can also be used as a high-precision CNC lathe.

Turning Features: Turning is a method of cutting a workpiece on a lathe using the rotation of the workpiece relative to the tool. Turning is the most basic and common cutting method. Most workpieces with revolving surfaces can be processed by turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads, and rotary forming surfaces. Common lathes can be divided into horizontal lathes, floor lathes, vertical lathes, turret lathes, and profiling lathes, most of which are horizontal lathes. Turning has higher efficiency than grinding, turning often adopts a large cutting depth and high workpiece speed, and its metal resection rate is usually several times that of grinding processing. During vehicle machining, one loading clamp can complete a variety of surface machining, while the grinding requires multiple installations, so the auxiliary time is short and the position accuracy between the machining surfaces is high.

Details

FAQ 1. who are we? We are based in Guangdong, China, and started in 2008, selling to Domestic Market(60.00%), Eastern Asia(20.00%), North America(10.00%),Western Europe(10.00%). There are a total of about 51-100 people in our office. 2. how can we guarantee quality? Always a pre-production sample before mass production; Always final Inspection before shipment; 3. what can you buy from us? Fasteners, Screws, Hardware customized, Drawer Slide, springs 4. why should you buy from us not from other suppliers? It is a professional hardware manufacturer and has over 10 years of production experience, a professional staff team and service. |

|

Aluminum 7075 CNC Machining Parts Milling Turning 50um Teflon Coating 30um |

|

CNC customized aluminum alloy material parts machining service |

|

Precision CNC Machined Aluminum Components Customized With Tolerance 0.01mm |

|

OEM Machining Aluminum Parts CNC Machining Services for Custom Parts |

|

Custom Heavy Duty Linear Motion Rails CNC Machining Aluminum Parts For Medical Flexible Arms |

|

Customized CNC Machining Services For Aluminum Alloy Material Parts |