Custom precision injection molded plastic boxes

|

|

What Are Custom Precision Injection Molded Plastic Boxes?

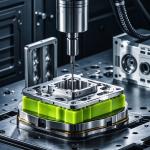

Custom precision injection molded plastic boxes are enclosures made using injection molding, a highly efficient manufacturing process that involves injecting molten plastic into a precisely designed mold. The process allows for the creation of intricate shapes and features with tight tolerances, making it perfect for custom applications where accuracy, strength, and functionality are key. Injection molding is ideal for producing large quantities of plastic boxes with consistent quality and high precision. These boxes can be used for a variety of purposes, including housing electronics, storing tools, protecting machinery components, and more. The ability to customize the design, material, color, and size makes these plastic boxes suitable for a broad range of industries.

Benefits of Custom Precision Injection Molded Plastic Boxes

2.Durability and Strength Custom injection molded plastic boxes are made from a variety of durable materials that can withstand harsh conditions. Depending on the application, materials like ABS, polycarbonate, or polypropylene can be chosen for their strength, impact resistance, and longevity. These boxes are designed to offer superior protection from external elements like moisture, dust, and physical impact.

3.Cost-Effective Production for High Volumes While the initial cost of tooling for injection molding may be higher, it becomes extremely cost-effective for large production runs. Custom precision injection molded plastic boxes are ideal for companies needing to produce large quantities of boxes without sacrificing quality or consistency. The speed and efficiency of injection molding ensure faster turnaround times, which helps meet tight production schedules.

4.Design Flexibility One of the key advantages of custom precision injection molded plastic boxes is the high degree of design flexibility they offer. Injection molding allows manufacturers to create complex shapes, intricate features, and detailed texturing that would be difficult or costly to achieve with other manufacturing methods. You can design your plastic box to meet specific functional requirements, such as ventilation slots, mounting brackets, or cable openings, while also ensuring a high-quality aesthetic finish.

5.Enhanced Aesthetic and Branding Opportunities In addition to their functional advantages, custom precision injection molded plastic boxes can be designed with visual appeal in mind. The injection molding process allows for various colors, textures, and finishes, providing an opportunity to align your packaging with your brand’s aesthetic. The surface can also be customized for branding with logos, graphics, or text, making these boxes not only functional but an extension of your brand identity.

6.Tight Tolerances for Seamless Assembly Custom precision injection molded plastic boxes ensure that the components inside or around the box fit seamlessly. Tight tolerances are especially important when the plastic boxes are used for complex electronic or mechanical assemblies, where even a slight deviation could affect performance. The precision provided by injection molding reduces the need for additional adjustments or modifications during assembly.

The Injection Molding Process for Custom Precision Plastic Boxes

Applications of Custom Precision Injection Molded Plastic Boxes

Conclusion

Custom precision injection molded plastic boxes offer a versatile, cost-effective solution for industries requiring high-quality, durable enclosures for their products. Whether you need intricate designs, high-volume production, or a specific aesthetic, injection molding provides the flexibility, precision, and scalability needed to meet your requirements. With superior precision, durability, and customization options, custom precision injection molded plastic boxes are the perfect solution for your next project. Choose a reliable manufacturing partner to ensure that your custom plastic boxes are produced to the highest standards, helping your products stay protected and performing at their best.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

| Product Tags: Precision Computer injection molding plastic parts POM injection molding plastic parts |

|

High Durability Injection Molding Parts With Grinding / EDM / QC Processing |

|

Custom injection mold parts |

|

Customized Injection Molded Plastic Parts For Various Public Area Applications OEM |

|

Durability Public Area Injection Molded Plastic Parts For Airports And Hotels |

|

Processing plastic injection mold CNC parts |

|

CNC machining custom size injection plastic mold parts |