Custom ABS Parts Injection Molding

|

|

In the world of modern manufacturing, plastic components are essential in countless products across industries such as automotive, electronics, consumer goods, healthcare, and industrial equipment. Among the many thermoplastics available today, ABS (Acrylonitrile Butadiene Styrene) stands out as a versatile, durable, and easy-to-mold material. When combined with the power of injection molding, ABS becomes an ideal choice for producing high-quality, cost-effective plastic components.

What Is ABS Plastic?

ABS is widely favored for its excellent balance of mechanical strength, dimensional stability, and aesthetic appeal. It is easily processed, dyed, or finished, making it ideal for both functional and decorative parts.

What Is Custom ABS Parts Injection Molding?

Custom ABS parts injection molding refers to the creation of injection-molded ABS parts tailored to specific design and functional requirements. These parts can range from simple housings to complex, multi-functional assemblies.

Key Characteristics:

Advantages of Injection Molding ABS Plastic

2.Dimensional Stability

Custom ABS parts maintain tight tolerances and resist warping or distortion over time.

3.Good Aesthetics

ABS can be molded into glossy, matte, or textured surfaces and dyed in a wide range of colors for visual appeal.

4.Chemical Resistance

Useful in environments where exposure to oils, fats, or cleaning agents is expected.

5.Ease of Machining and Post-Processing

ABS parts can be easily painted, plated, glued, or laser engraved after molding.

The Custom Injection Molding Process for ABS

CAD modeling and prototyping to meet exact part specifications.

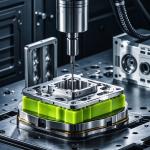

2.Mold Fabrication

Precision tooling made from steel or aluminum for long-term use or rapid prototyping.

3.Material Preparation

ABS pellets are dried and melted to optimal processing temperatures.

4.Injection Molding

Molten ABS is injected into the mold at high pressure, then cooled and ejected.

5.Quality Inspection

Dimensional and visual inspections ensure that each part meets customer standards.

6.Secondary Operations (Optional)

Painting, ultrasonic welding, or assembly as needed.

Applications of Custom ABS Injection Molded Parts

1.Automotive

2.Electronics

3.Medical Devices

4.Consumer Products

5.Industrial Equipment

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

High Durability Injection Molding Parts With Grinding / EDM / QC Processing |

|

Custom injection mold parts |

|

Customized Injection Molded Plastic Parts For Various Public Area Applications OEM |

|

Durability Public Area Injection Molded Plastic Parts For Airports And Hotels |

|

Processing plastic injection mold CNC parts |

|

CNC machining custom size injection plastic mold parts |