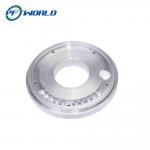

Aluminum parts sandblasting CNC turning composite electronic equipment

|

|

If you're in the business of designing or building electronic equipment—especially composite or high-performance setups—you already know that the smallest parts can make the biggest difference. When it comes to performance, heat dissipation, durability, and aesthetics, precision aluminum parts are hard to beat.

CNC Turning = Clean, Precise, Repeatable

When used for electronic hardware, CNC turning ensures:

In composite systems—where aluminum may be used with plastic, carbon fiber, or PCBs—fit is critical. A poorly made part can cause misalignment, signal interference, or even overheating.

Why Sandblasting? It’s More Than Just a Pretty Finish

That smooth matte look isn’t just for show—it also helps with heat dissipation, scratch resistance, and gives the parts a more professional appearance inside high-end gear.

Perfect for Composite Electronic Builds

You can also add cutouts, grooves, slots, or flanges to fit with carbon fiber panels, 3D-printed shells, or injection-molded components. The result? A hybrid build that looks sharp and performs even better.

Real-World Use Cases

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

Small CNC Turning Precision Parts |

|

Custom CNC Turning Lathe Parts with Black Surface Treatment and ODM Service High Precision ±0.005mm Tolerance |

|

Zinc Plated CNC Turning Parts Long Lasting with CNC Drilling / Tapping Surface Protection |

|

Custom Metal Fabrication CNC Turning Spare Parts 3 4 5 6 Axis CNC Machining Service |

|

OEM CNC Turning Materials for High Precision Sensor Parts in Mechanical Industry |

|

CNC Turning Parts Aluminum Copper Stainless Steel Precision Machining Components ISO Certified |