High Precision Black ABS Injection Molding Parts Customized for Your Customization Needs

|

What Are High Precision Black ABS Injection Molding Parts?

Injection molding is a manufacturing process in which molten plastic is injected into a mold cavity, where it cools and solidifies into the desired part shape. ABS is a popular thermoplastic polymer used in this process due to its excellent combination of strength, toughness, and impact resistance, along with its ability to be molded into precise, intricate shapes.

When we talk about high precision black ABS injection molding parts, we're referring to parts that are produced using state-of-the-art injection molding techniques, ensuring tight tolerances and excellent surface finishes. These parts are typically used in applications where both the physical properties of the material and the dimensional accuracy of the part are critical.

Black ABS is particularly valued for its sleek, professional appearance, chemical resistance, and durability. Whether you’re producing automotive components, electronic enclosures, consumer goods, or industrial parts, high precision black ABS injection molding parts offer the strength and aesthetics required for demanding applications.

Why Choose High Precision Black ABS Injection Molding Parts?

1.Unmatched Durability and Impact Resistance One of the key benefits of ABS as a material is its exceptional toughness. It can withstand impact, wear, and abrasion, making it ideal for high-precision injection molding parts that need to endure harsh environments. Whether it’s a mechanical component or a protective housing, black ABS parts provide the durability required for long-lasting performance.

2.Superior Aesthetic Quality The black finish of ABS provides a sleek and professional look that is highly desired in consumer-facing products like electronics casings, automotive interior parts, and appliances. The material also offers excellent color stability, meaning the deep black finish remains consistent over time, even with exposure to UV light and various environmental factors.

3.Customization for Complex Designs One of the greatest advantages of ABS injection molding is its versatility in creating complex, custom shapes. Whether you need intricate features, custom dimensions, or unique geometries, high precision ABS injection molding allows you to realize your design vision with minimal limitations. This flexibility makes it the perfect choice for industries that require parts tailored to specific functional or aesthetic needs.

4.Precision and Tight Tolerances High precision black ABS injection molding parts are produced with tight dimensional tolerances, ensuring that every component fits perfectly within your assembly. The high-precision nature of the process minimizes the need for secondary machining or finishing, reducing production time and costs while ensuring consistent quality.

5.Cost-Effective for High-Volume Production While ABS injection molding may involve initial tooling costs, it becomes highly cost-effective when producing large volumes of parts. The injection molding process is highly automated, meaning that once the mold is created, parts can be produced quickly and at a low per-unit cost, making it ideal for mass production runs.

Advantages of Customizing High Precision Black ABS Injection Molding Parts

Customizing high precision black ABS injection molding parts offers a multitude of benefits that allow you to create parts tailored to your exact specifications:

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

High Durability Injection Molding Parts With Grinding / EDM / QC Processing |

|

Custom injection mold parts |

|

Customized Injection Molded Plastic Parts For Various Public Area Applications OEM |

|

Durability Public Area Injection Molded Plastic Parts For Airports And Hotels |

|

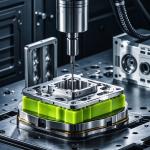

Processing plastic injection mold CNC parts |

|

CNC machining custom size injection plastic mold parts |