Processing injection molding sports equipment precision

|

|

What is Injection Molding?

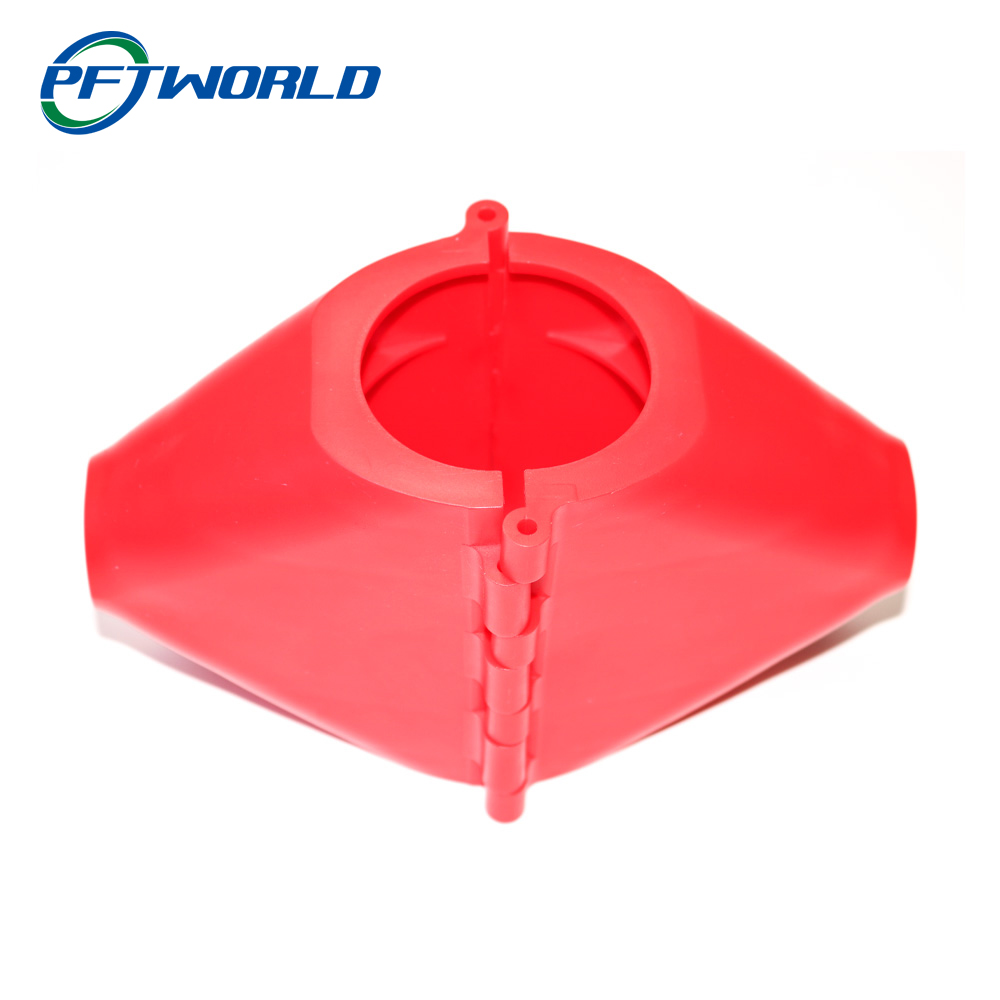

Injection molding is a versatile manufacturing process where molten material, usually plastic or rubber, is injected into a mold to form a part. It’s widely used for producing complex shapes with high accuracy, making it ideal for sports equipment.

2. Advantages of Injection Molding in Sports Gear

Applications of Injection Molding in Sports Equipment

1.Protective GearFrom hockey helmets to shin guards, injection molding produces protective equipment that meets rigorous safety standards. The ability to use impact-resistant materials ensures the gear can withstand heavy use while providing maximum protection. 2.Fitness EquipmentCustom handles, weights, and structural components for fitness machines are often produced through injection molding. The process allows for consistent grip textures and ergonomic designs tailored to user preferences. 3.Ball Sports EquipmentInjection molding contributes to the precision crafting of soccer balls, basketball grips, and tennis racket grommets, where accuracy directly impacts performance. 4.Extreme Sports GearFor skateboards, snowboards, and even surfboards, injection molding enables lightweight yet durable designs that can withstand extreme conditions.

Factory Customization: Elevating Sports Equipment Design

1. Personalized Fit and FunctionalityCustom molds allow manufacturers to produce equipment tailored to individual needs, such as:

2. Aesthetic CustomizationInjection molding supports the integration of unique color schemes, textures, and logos, enabling brands to deliver a distinct visual identity for their products. 3. Rapid PrototypingWith advancements in CNC machining and 3D printing, factories can quickly develop molds for prototype testing, ensuring designs meet customer expectations before mass production.

Precision Injection Molding: The Future of Sports Equipment Manufacturing

1.Technological AdvancementsThe integration of AI-driven controls in injection molding machines enhances precision, allowing for real-time adjustments and reduced waste. Multi-material molding is another innovation enabling the creation of complex parts with varied properties, such as soft grips and rigid cores. 2.Sustainability InitiativesMany factories now prioritize sustainable manufacturing practices, using recyclable materials and optimizing processes to minimize energy consumption. Precision injection molding supports this by reducing material waste through accurate mold designs. 3.Industry 4.0 IntegrationThe adoption of smart manufacturing systems streamlines operations, from mold development to production monitoring. IoT-enabled injection molding machines provide data insights that improve efficiency and product quality.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

5AXIS Anodize Turned Plastic Parts , PCB CNC Machining Rapid Prototype |

|

Anodizing CNC Machining Plastic Parts Electrophoresis Surface Acrylic ABS POM |

|

POM PEEK Acrylic Machining Plastic Parts 100mm For Furniture Security |

|

Bronze PTFE Plastic Parts CNC Machining Anodized Aluminum Titanium |

|

OEM CNC Turning Machining Plastic Parts Silkscreen Acrylic ABS Material |

|

PEEK PPS PTFE CNC Machining Plastic Parts Laser Engraving Spare |