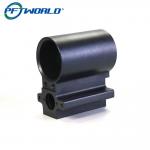

High Precision CNC Aluminum Machining Parts

|

|

What Are High Precision CNC Aluminum Machining Parts?High precision CNC aluminum machining parts refer to custom-engineered components made from aluminum alloys, produced using advanced CNC machining techniques. CNC machining utilizes automated tools and computer programming to shape aluminum with exceptional accuracy and consistency. This process allows for the creation of parts with tight tolerances, complex geometries, and a smooth finish, all of which are essential for high-quality performance in demanding applications. Aluminum, being lightweight, corrosion-resistant, and highly versatile, is a preferred material for many applications. The precision machining process ensures that aluminum components meet the highest industry standards, offering both functionality and aesthetic appeal.

Key Applications of High Precision CNC Aluminum Machining Parts

High precision CNC aluminum machining parts are used in various industries and applications that demand high-quality components. Some of the key areas where these parts are essential include: 1.Aerospace IndustryIn the aerospace industry, precision and weight reduction are critical. CNC machining of aluminum is used to produce lightweight yet strong components, such as structural parts, engine components, brackets, and housings. Aluminum's natural corrosion resistance also makes it ideal for parts exposed to extreme conditions in flight.

2.Automotive IndustryThe automotive industry relies on CNC-machined aluminum parts for producing components that must be lightweight, durable, and able to handle high-performance requirements. Aluminum’s combination of strength and lightweight properties makes it an ideal choice for engine parts, transmission components, and even interior trim.

3.Electronics and Consumer GoodsIn the electronics and consumer goods sectors, CNC-machined aluminum parts are used for creating precise enclosures, casings, and structural elements. The sleek appearance, strength, and heat dissipation properties of aluminum make it a popular choice for high-end electronic devices, such as smartphones, laptops, and home appliances.

4.Medical DevicesThe medical industry requires CNC-machined aluminum parts that are not only precise but also hygienic and durable. Aluminum’s lightweight and corrosion-resistant properties make it ideal for components like surgical instruments, medical implants, and diagnostic equipment. CNC machining ensures these parts are produced to exacting standards, which is critical in the medical field.

5.Industrial Machinery and EquipmentCNC machining is widely used to produce parts for industrial machinery and heavy equipment. These parts need to withstand significant wear and tear while maintaining their dimensional integrity. The durability of aluminum, combined with the precision of CNC machining, ensures that components such as gears, brackets, and support structures are reliable and long-lasting.

The CNC Machining Process for High Precision Aluminum Parts

The high precision CNC machining process for aluminum parts involves several key steps: 1.Design and PrototypingThe process begins with creating a digital design of the part using CAD software. The design is then converted into machine-readable code (G-code) that directs the CNC machine on how to cut, shape, and finish the part. 2.Material SelectionSelecting the right grade of aluminum is crucial for ensuring that the part meets the desired performance standards. Common aluminum alloys used in CNC machining include 6061, 7075, and 2024, each offering specific mechanical properties tailored to different applications. 3.CNC Machining OperationsUsing CNC mills, lathes, or multi-axis machines, the aluminum part is shaped according to the design specifications. Depending on the complexity of the design, the CNC machine can perform a variety of operations, including milling, turning, drilling, and tapping. 4.Finishing and PolishingAfter machining, the part may undergo additional finishing steps, such as anodizing, deburring, or polishing to improve the surface finish, enhance corrosion resistance, and provide a sleek appearance. 5.Quality Control and InspectionBefore delivery, the CNC-machined aluminum parts are thoroughly inspected for precision, surface quality, and adherence to the required specifications. Tools like coordinate measuring machines (CMM) and visual inspection ensure that the final product meets the highest standards.

Conclusion

High precision CNC aluminum machining parts are essential in industries that demand exceptional quality, performance, and durability. The combination of CNC machining and aluminum’s desirable properties allows for the production of custom, high-performance parts that meet the most stringent requirements. Whether you're involved in aerospace, automotive, medical, or electronics, CNC machining ensures that your aluminum components are manufactured to the highest standards of precision and reliability. Partner with

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

Aluminum 7075 CNC Machining Parts Milling Turning 50um Teflon Coating 30um |

|

CNC customized aluminum alloy material parts machining service |

|

Precision CNC Machined Aluminum Components Customized With Tolerance 0.01mm |

|

OEM Machining Aluminum Parts CNC Machining Services for Custom Parts |

|

Custom Heavy Duty Linear Motion Rails CNC Machining Aluminum Parts For Medical Flexible Arms |

|

Customized CNC Machining Services For Aluminum Alloy Material Parts |