OEM CNC Machining Aluminum Parts Services

|

|

What Are OEM CNC Machining Aluminum Parts Services?OEM CNC machining aluminum parts services involve using advanced CNC machines to precisely cut, shape, and finish aluminum materials into custom parts as per Original Equipment Manufacturer (OEM) specifications. This service is often used to create parts with highly intricate designs, tight tolerances, and smooth finishes, making it perfect for industries where performance and quality are paramount. CNC machines are programmed to execute a variety of operations, including milling, turning, drilling, and grinding, on aluminum to produce parts such as brackets, housings, gears, and connectors. This method allows for the mass production of parts with a high degree of repeatability and accuracy, ensuring that each part meets exact design specifications.

Common Applications of OEM CNC Machining Aluminum Parts

1.Aerospace and Aviation

2.Automotive

3.Electronics

4.Medical Devices

5.Industrial Machinery

The Benefits of OEM CNC Machining Aluminum Parts Services

Conclusion

OEM CNC machining aluminum parts services provide the precision, reliability, and efficiency required to meet the demands of various industries. With their lightweight strength, corrosion resistance, and customization capabilities, CNC-machined aluminum parts are the perfect solution for applications ranging from aerospace to medical devices and everything in between.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

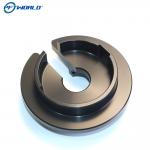

High Demand OEM Precision CNC Machining Milling Metal Stainless Steel Parts Services |

|

CNC Machining Milling Metal Sandblasting Aluminum Precision Parts |

|

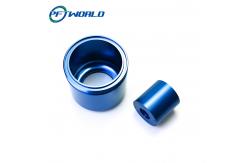

OEM Precision CNC Milling and Turning Anodized Aluminum Metal Parts Processing Services |

|

Precision Customized Anodized CNC Hardware Aluminum Machining Services Parts CNC Milling |

|

CNC Precision Anodized Aluminum Machining CNC Metal Service Aluminum Milling Parts |

|

Aluminum CNC Precision Metal Milling Turning Parts CNC Machining Anodized Service Parts |