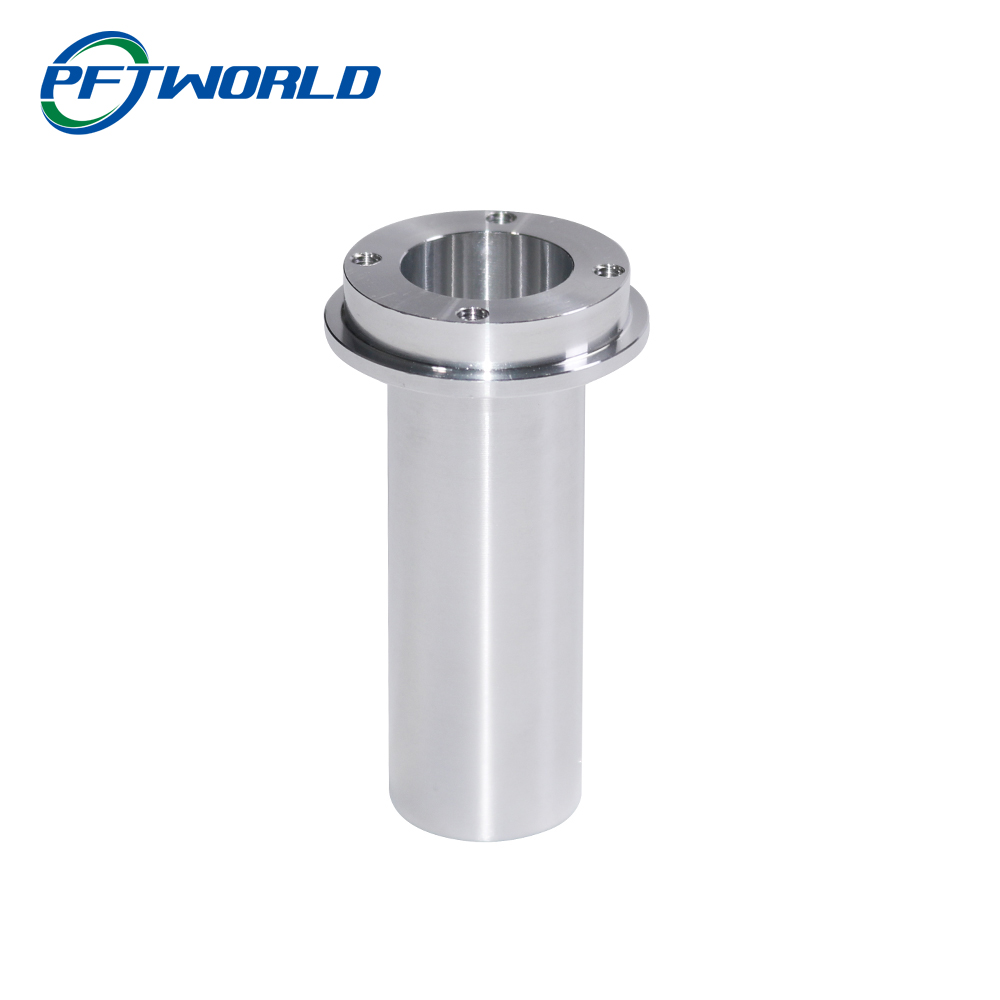

Precision machined aluminum parts

|

|

What Are Precision Machined Aluminum Parts?

Precision machined aluminum parts are components made from aluminum alloys that undergo advanced machining processes like CNC milling, turning, and drilling to achieve precise shapes, sizes, and finishes. These parts are engineered to meet high-performance requirements, offering superior accuracy, reliability, and strength.

Why Choose Precision Machined Aluminum Parts?

1. Lightweight yet StrongOne of the primary advantages of aluminum is its lightweight nature without compromising on strength. Precision machined aluminum parts are ideal for industries like aerospace, automotive, and electronics, where minimizing weight is critical without sacrificing durability. Aluminum alloys such as 6061, 7075, and 2024 offer outstanding strength-to-weight ratios, making them perfect for high-performance applications.

2. Superior Precision and Tight TolerancesThe precision machining process allows for extremely tight tolerances, down to 0.01mm or even finer, ensuring that your aluminum parts fit perfectly in complex assemblies. This level of accuracy is vital for industries where even the smallest discrepancy can affect performance, such as in medical devices, electronics, and robotics.

3. Corrosion ResistanceAluminum is naturally corrosion-resistant, making it an ideal material for parts exposed to harsh environments. When precision machined, the aluminum maintains its ability to resist rust and degradation, which is essential for parts used in outdoor or marine environments. Surface treatments such as anodizing can further enhance its resistance to wear and corrosion.

4. Customization and FlexibilityPrecision machining allows for the creation of highly customized aluminum parts tailored to your specific needs. Whether you require complex geometries, intricate designs, or multi-functional parts, CNC machining provides the flexibility to produce parts that meet your exact requirements. Additionally, the ability to quickly adapt designs makes aluminum machining ideal for rapid prototyping.

5. Cost-Effective for High-Volume ProductionDespite the precision and quality involved, precision machined aluminum parts are highly cost-effective, especially when produced in high volumes. CNC machining allows for high efficiency and reduced material waste, which helps to keep production costs down. As production runs scale up, the unit cost decreases, making it ideal for large-scale manufacturing.

Applications of Precision Machined Aluminum Parts

1. Automotive IndustryThe automotive industry benefits greatly from precision machined aluminum parts due to the material's lightweight nature, strength, and resistance to corrosion. Aluminum parts are commonly used in engine components, brackets, mounts, chassis, and body panels to reduce overall vehicle weight, improve fuel efficiency, and enhance performance.

2. Aerospace and AviationIn aerospace, where performance, reliability, and weight are crucial, precision machined aluminum parts play a pivotal role. The aerospace industry relies on aluminum alloys for manufacturing critical components like aircraft frames, landing gear, wings, and engine parts. Aluminum’s resistance to heat, strength, and lightweight nature make it indispensable for the industry.

3. Medical DevicesPrecision machined aluminum parts are used in the medical industry for products like surgical instruments, implantable devices, medical equipment housings, and prosthetics. Aluminum’s biocompatibility, strength, and lightweight properties make it an ideal material for devices that need to be both durable and easy to handle.

4. Electronics and Consumer GoodsIn electronics, precision machined aluminum parts are used for the enclosures, heat sinks, brackets, and mounting components in devices such as smartphones, laptops, and LED lighting systems. Aluminum’s ability to dissipate heat efficiently is especially beneficial for electronic components that generate high levels of heat.

5. Industrial Machinery and EquipmentThe industrial machinery sector requires parts that can withstand harsh working environments. Precision machined aluminum parts are used for components like machine frames, tooling, bearings, and shafts, which must endure high loads and constant motion.

Conclusion: Elevate Your Manufacturing with Precision Machined Aluminum Parts

Precision machined aluminum parts offer unparalleled accuracy, strength, and versatility, making them the ideal solution for a wide range of industries. By choosing precision machining for your aluminum parts, you ensure that your products meet the highest standards of quality, performance, and reliability.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

| Product Tags: Precision CNC Machined Aluminum Spare Parts Auto equipment CNC Precision Aluminum Parts |

|

Aluminum 7075 CNC Machining Parts Milling Turning 50um Teflon Coating 30um |

|

High-Performance CNC Machined Aluminum Parts for Modern Industrial Manufacturing |

|

Custom CNC Machining Service for Aluminum Alloy Material Parts with Custom Designs and Aluminum Material Capabilities |

|

Precision CNC Machined Aluminum Components Customized With Tolerance 0.01mm |

|

OEM Machining Aluminum Parts CNC Machining Services for Custom Parts |

|

Custom Heavy Duty Linear Motion Rails CNC Machining Aluminum Parts For Medical Flexible Arms |