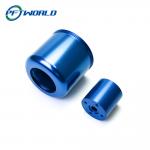

High-precision machining of aluminum CNC milling parts

|

|

Product Description:

In the competitive world of modern manufacturing, the demand for high-precision machining of aluminum CNC milling parts has never been greater. Whether you're in the aerospace, automotive, medical, or electronics industry, the need for components that meet exacting specifications, superior performance standards, and fast turnaround times is critical. CNC (Computer Numerical Control) milling offers unparalleled precision and efficiency, particularly when machining aluminum, a lightweight, durable, and versatile material.

What is High-Precision Machining of Aluminum CNC Milling Parts?CNC milling is a computer-controlled manufacturing process that uses rotary cutters to remove material from a workpiece in a precise and efficient manner. When it comes to high-precision machining, the goal is to achieve parts with extremely tight tolerances, ensuring perfect fit and function. Aluminum, a material known for its light weight, strength, and excellent machinability, is often chosen for high-precision parts in a wide range of industries. The high-precision machining of aluminum CNC milling parts involves using advanced CNC machines equipped with sophisticated software to create parts with a high degree of accuracy and repeatability. The process allows for the creation of intricate and complex geometries, ensuring that every part is manufactured to meet the exact specifications of the design, whether it's for a small prototype or a large production run.

Benefits of High-Precision CNC Milling for Aluminum Parts:1. Incredible Accuracy and RepeatabilityCNC milling machines are capable of achieving extremely tight tolerances, often within fractions of a millimeter or even micrometers. This level of precision ensures that each aluminum CNC milling part meets exact design specifications, which is crucial for applications where even slight variations could compromise performance. Whether you need a batch of identical parts or a single custom component, CNC milling guarantees consistent quality across all units. 2. Complex Geometries and Intricate DesignsOne of the key advantages of CNC milling is its ability to create parts with complex shapes and intricate features. From 3D contours and cavities to small, detailed features, CNC milling can produce highly detailed aluminum parts that are difficult or impossible to achieve with traditional machining methods. Custom geometries, such as precise holes, slots, and threads, can be easily incorporated into your design. 3. Efficiency and SpeedHigh-precision CNC milling is also incredibly efficient. Once the design is programmed into the CNC machine, the machining process can run automatically, reducing the need for manual labor and minimizing the potential for human error. This allows manufacturers to produce high-quality aluminum parts quickly, with faster turnaround times and reduced lead times, even for complex or custom designs. 4. Reduced Material WasteCNC milling is a subtractive manufacturing process, which means material is removed from a solid block to create the desired part. This process allows for more efficient use of materials compared to other methods like casting or forging, resulting in less scrap and waste. For aluminum parts, which can be costly, this reduced material waste translates into cost savings for manufacturers. 5. Cost-Effectiveness for Both Small and Large BatchesCNC milling is not only ideal for mass production but is also cost-effective for producing smaller batches or even single, custom parts. Whether you're prototyping a new design or need a small volume of precision parts, high-precision CNC milling can accommodate your needs at an affordable price point.

Industries That Benefit from High-Precision Aluminum CNC Milling

ConclusionThe high-precision machining of aluminum CNC milling parts offers unmatched benefits for manufacturers across various industries. The ability to create complex designs with extreme accuracy, combined with aluminum's excellent properties, makes CNC milling the go-to process for high-performance components. Whether you need a custom one-off part or a high-volume production run, working with a factory that specializes in CNC milling ensures that you get the precision, quality, and efficiency required to meet your specific needs. By choosing factory-customized solutions, you can optimize your production process, reduce lead times, and achieve the best results for your aluminum parts.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

| Product Tags: CNC Milling Aluminum Engineering Components High Precision CNC Milling Component |