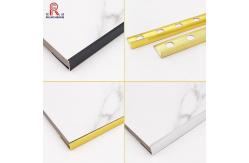

Brushed Ceramic Tile Metal Edge Trim , 8.5mm Aluminum Trim Tile L Shape

|

|

Anodized L Shape Aluminum Tile Trim Alloy Metal Corner Edge Ceramic

Protection

Use 1.Select profiles according to tile thickness. 2.Trowel tile adhesive over the area that forms the perimeter of the tiled covering. 3.Press the perforated anchoring leg of the profiles into the tile adhesive and align. 4.Trowel additional adhesive over the perforated anchoring leg to ensure full coverage. 5.Solidly embed the tiles so that the tiled surface is flush with the top of the profile (the profile should not be higher than the tiled surface, but up to approximately 1 mm lower). 6.The tile is set to the lateral joint spacer, which ensures a uniform joint of 1.5 mm. With the stainless steel profiles, leave a space of approximately 1.5 mm. 7.Fill the joint completely with grout.

Specification

|

||||||||||||||||||||||

| Product Tags: L Shape aluminum trim tile 8.5mm ceramic tile metal edge trim Brushed ceramic tile metal edge trim |

|

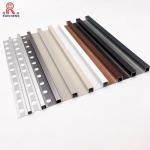

Powder Coating White Aluminum Tile Trim Square Edge Shape 3m Length T8 |

|

2mm Aluminum Tile Edge Trim , Anodized Square Ceramic Gold Metal Tile Trim |

|

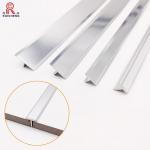

Brushed Aluminum Tile Trim 7.5mm Height Ceramic Protection T Shape |

|

T Shaped Aluminium Trim 0.55mm Thickness T3 Temper Anodizing Oxidation |

|

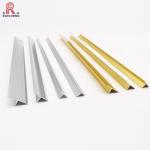

Anodised Aluminum Tile Trim 2mm Thickness Triangle Alu 6463 Material |

|

Polished Tile Aluminum Edge Trim , Triangle Tile Trim 10mm Height |