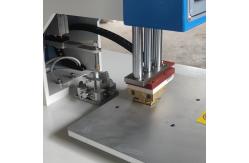

Woven Making Fabric Label Heat Press Machine Transfer Sublimation Printing Machine

|

|

FuLund factory Printer Woven Making Fabric Label Heat Press Machine Transfer Sublimation Printing Machine CE verified Semi-automatic label hot stamping machine suitable insole leather notebook cardboard

Fulund has a long history since its establishment in 1999. Due to

the needs of development, the original brand (TYL) expanded the new

brand Fulund in 2022 . Fulund has customers all over the world,such

as international brands shoe manufacturer.

Scope of application: Widely use in the clothes, bags, shoes, leather and other relevant industries thermal transfer for label.

Features: 1, Intellectualized human- machine interface, Chinese/English/Vietnamese systems, easy to operate. 2, Use the high stability rotary cylinder, infeeding label faster, higher precision. 3, Can form a dedicated label printer, can print the label timely according to the requirements. 4, Easy to operate, worker only need put the material according the locating piece, novices can easy to handle, greatly reduce the factory training cost, and the output will not decrease when the skilled worker leaves. 5, High precision, the maximum yield 1200pcs/hour. 6, Temperature, pressure, pressing time can be adjusted according to the press effect, and also can set the trouble alarm of temperature trouble alarm, pneumatic pressure to ensure the product quality.

Contrast:

Conclustion:1,Use FLD-590F, higher accuracy location than manual location, high efficiency, can save more labor cost. For example: Monthly labor cost $547, if use the FLD-590F, the label cost can save 547x12=$6564 a year. 2,FLD-590F is less depending on skilled, ensure the daily capacity.

|

|||||||||||||||||||||||||||||||||||||||

| Product Tags: Fabric Label Heat Press Machine Woven Label Heat Press Machine |

|

Hot Press Label Hot Stamping Machine Pneumatic For Nike Shoe |

|

Nike Aj Adidas Shoe Manufacturing Equipment for Labels Labeling And Printing |

|

Automatic Label Hot Stamping Machine , Heat Press Printing Machine for Shoe Making |

|

Industrial Shoe Making Machine Automatic Pneumatic For Label Labeling |

|

Multifunctional Pneumatic Label Hot Stamping Machine For Paper Leather Fabric |

|

Nike Aj Adidas Shoe Making Equipment for Flat Surface Label Printer |