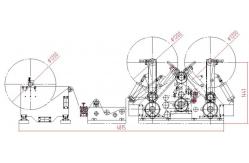

1200mm NCR Paper Roll Slitter Rewinder Carbonless Paper Slitting Rewinding Machine

|

|

FOCUS FM1850 High Speed 1200mm Max NCR Slitter Rewinder Carbonless Paper Slitter Rewinder

Description of Main Machine Parts

1. Unwind parts 2) Unwind tension control 2. Main Machine parts 2) The web roll, spreader roll, and guide roll, are made of aluminum alloy from Ningbo China dia.120mm, where bigger wrap angle is needed, the roll diameter is 150mm 3) The “S” lead roll is pattern grooved and driven from the main motor through timing belt, where as the backing roll is not driven. Both the “S” lead roll and the backing roll are PU covered. By choosing the right hardness of the PU cover it is possible to slit CFB paper on this machine without showing any color/imaging. The Diameter of the backing roll is 270mm. The backing roll is equipped with a rubber covered rider roll. The function of the rider roll is to hold the paper lead in place during machine stop or threading and to facilitate better threading. The roll is loaded by pneumatic cylinders. 4) Slitting Knife The top knife shaft may be axially micro-adjusted by manual knife setting device for engaging the top and bottom knives. Material for top knife is high speed steel and for bottom knife is tool steel. 5 pcs each of top and bottom knives are included. 5) The main motor is inverter controlled three-phase AC motor (11kW-6P) on which is installed Koyo encoder, and the inverter is from YASKAWA Japan. The main motor drives the main lead roll via timing belt. 6) All rolls (driven or non driven rolls, or rubber covered rolls) have been dynamically balance tested. 7) Trim removal by suction blower, blower motor:3 KW 3. Rewind parts On the proposed “Center Surface slitter rewinder” it is possible to apply both the "center rewinding" and the "center surface rewinding" techniques. 2) Rewind shafts: 3”imported air shafts, 2 pcs, max load per airshaft is 1500kg. 3) Rewind motors (18.5KW-6P): 2 inverter controlled three-phase AC motors with Koyo encoder, YASKAWA inverter, each rewind shaft is driven from the timing belt by its own motor. The contact pressure between the machine roller and the rewound paper roll is controlled by means of a P/E proportional valve. The winding tension is taper- controlled, and additionally the contact pressure is proportionally controlled and can be maintained constant irrespective of rewound paper roll diameter. 4) Length count 5) Different Taper factor for different paper grades for meeting the printing requirement. 6) Rewind shaft stabilization brakes for stabilizing the rewind rolls. 7) Rewound paper rolls are off-loaded from the rewinding stations by an overhead crane to be supplied by the customer.

Technical Data

SUCCESSFUL MACHINE PROJECTS

THERMAL PAPER COATING MACHINE PRODUCTION PROCESS

CUSTOMER FEEDBACK

FOCUS attends more than 15 exhibitions of carbonless paper/thermal

paper/paper coating machine every year all over the world to meet

and service clients face to face. China Manufacturer BPA Free Blue Imaging Black Imaging Wood Pulp

45GSM/48GSM/55GSM/58GSM/60GSM/65GSM/70GSM/80 GSM Thermal Paper Roll

|

| Product Tags: 1200mm paper roll slitter rewinder NCR paper roll slitter rewinder 50HZ paper slitting rewinding machine |

|

Thermal Paper Slitting Machine for Performance |

|

Siemens Electrical Control System Thermal Paper Slitting Machine For Simple Operation |

|

Automatic Marking Device Thermal Paper Converting Machine With Meter Counting |

|

Inflatable Shaft and Flattening Roller Thermal Paper Slitting Machine for Smooth Operation |

|

Siemens Complete Electrical Control System PLC Thermal Paper Slitting Machine |

|

900mm POS ATM Paper Converting Machine 200m/Min Thermal Paper Roll Cutting |