6 8 10 12 Nozzles Lubricant Oil Flow Meter Filling Machine Track Capping

|

|

6/8/10/12 Nozzles Bottle Oil Motor Oil Lubricant Oil Flow Meter Filling Machine Track Capping Machine Package Machines

Description 1.Control system---- SIEMENS PLC control system, random minitrimming filling measurement 2.Operation interface----Two rows of the color operation interface, Convenient operation,stable and reliable. 3.Function improvement----The feeding nozzle is equipped with filling blocker. This machine can realize diving filling according to the material properties.(this function can be selected) 4.Filling show---the filling result is displayed in the unit of

weight ,intuitive and clean 5.Electrical elements----Adopting international famous brand to ensure the remarkable quality, stability and high precision. 6.Machine elements----The parts contacted with the material use the 316 high-quality stainless steel and non-poisonous, anti-corrosive PTEF hose.Other machine parts use the 304 high-class stainless steel. 7.Expansion function----- We can carry out special configuration according to the customers’ requirements.(material airtight, heating and sterilizing etc.) 8.Counting detection----Real- time counting, reflecting the output directly. 9.Filling detection----No-bottle no-filling, it will not conduct filling if the bottles are not enough. 10.Function upgrading---We have designed intelligent weighing feedback system to realize the unmanned debugging function. 11.Environmental protection configuration----Equipped with eco-friendly frame, realizing more clean and sanitary operation environment.(this environmental protection configuration can be selected) 12.Maintenance condition----Fully accords to the GMP requirements,

easy to disassemble and clean. 13.Changing specification--According to the changing of market specifications 5L -25L large-dose packaging range, only in the same machine operation. To save the equipment cost for the customer. when changing filling specifications, just adjust, no need to change any components. easily done.

Feature: The whole pipeline can be made up of multiple PLC systems. Each system can be controlled independently and interlocked. It has the functions of self inspection of the system, fault alarm and display of motion state, precision, speed, adjustment and cumulative production. All the systems are equipped with man-machine interface, and all the parameters can be operated on the man-machine interface. Provide detailed pipeline control process flow chart and logic diagram. And the system can store multiple specifications, one key switch, no need for cumbersome settings.

The liquid level control and adjustment system of filling tank can be completed by product pump and self control function.

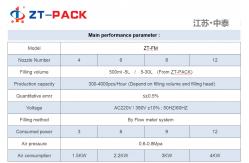

Parameters:

Details:

Factory: |

|||||||||||||||||||||

| Product Tags: 5L Flow Meter Filling Machine 12Nozzles Flow Meter Filling Machine PLC Lubricant Oil Filling Machine |

|

4000BPH Plastic Bottle Metcal Can Lubricant Oil Motor Oil 500ml-5L Piston Filling Machine Packaging Machine |

|

SS316 plastic bottle engine oil lube oil drum 5L by flow meter high speed 5000BPH Filling Machine |

|

SS316 Flow Meter Lubricant Oil Engine Oil Grease fast speed 5000BPH Plastic Bottle Filling Machine |

|

2l Lubricant Filling Machine Square 1000ml 12 Head Filling Machine |

|

1kw Ss316 Lube Oil Filling Machine 5l Automatic Bottle Filling Capping Labeling And Sealing Machine |

|

PLC Lubricant Filling Machine Automatic 220v Bottle Filling Capping And Labeling Machine |