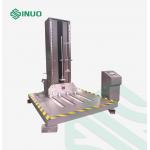

MIL-STD810G Water Cooled Electromagnetic Vibration Testing Machine

|

|

MIL-STD810G Water Cooled Electromagnetic Vibration Testing Machine

Equipment Overview

Vibration testing is the act of exciting or shocking a component or device to see how it would react in a real environment. The application range of vibration test is extremely wide, from industrial products such as circuit boards, aircraft, ships, rockets, missiles, automobiles and household appliances.

Laberton can provide you with the whole excitation and testing scheme, and prove the quality of the products for you according to national and international standards, such as GB, GJB, UL, JIS, DIN, ISO, BS, MIL, IEC and ASTM.

Vibration machine selection formula and vibration generator structure diagram The test conditions provided by custsomer’s company; Test type: Sine sweep; Random; Classic Shock; Frequency response range: 1-2700Hz Formula: A(g)=(2πf)2Dcm/980≒A=0.002DmmF2 D=A/0.002F2 F=M(kg) ×A(g)

Technical Parameters

Introduction of Product technology and function

The water-cooled vibrating table series has many advantages such as large thrust, strong bearing capacity, high cooling efficiency, and a maximum displacement of 76mm.

Meet various typical vibration test requirements for large electronic assemblies, automation devices, aerospace large components, artificial satellites, space and military systems.

When the trunnion system is specially designed and the client provides a suitable foundation, the system can start from a low frequency of 1Hz or even DC, whether it is sinusoidal or random vibration.

Random Performance Indicators

VCS5X random control function provides fast and precise random vibration control. The adaptive control algorithm based on the transfer function can quickly respond to the nonlinearity of the system, the resonance vibration point and the change of the dynamic load, greatly improving its control accuracy and obtaining a fast loop time.

Control method Equalization Method: Transfer Function Control loop: Adaptive control based on transfer function update, which can quickly respond to changes in system nonlinearity, resonance vibration points and dynamic loads control performance Dynamic range: 90dB Control accuracy: ±1dB Closed loop time: typical value 100mS drive signal A continuous Gaussian random signal. Control parameters Frequency range: from 0 to 145 Hz, 250 Hz, 290 Hz, 500 Hz, 585 Hz, 1000 Hz, 1170 Hz, 2000 Hz, 2340 Hz, 4000 Hz, 4680 Hz Resolution: 100, 200, 400, 800, 1600, 3200, 6400 spectral lines Control strategy: single channel control, weighted control, maximum value, minimum value Number of degrees of freedom (DOF): 12~3160 Clipping coefficient (sigma shear): 2~100 Stacking rate: None, 50%, 75% Target spectrum Crossover point: defined by magnitude or slope, the number of crossover points is not limited Crossover point calculation: Automatically calculate the crossover frequency value of each segment. Tolerance Spectrum: Define the alarm line and interrupt line in dB or % relative to the target spectrum Validity check: Automatically check the validity of the defined intersection points RMS tolerance limit: automatically calculated based on the tolerance spectrum or manually set by the user. RMS Calculation: Automatic calculation of displacement, velocity and acceleration RMS values and estimated peak values. RMS Adjustment: Adjust the RMS value manually or by setting the decibel conversion. Acceleration type: logarithmic, dB Engineering Units: Imperial, Metric Display: Automatically display the reference spectrum with tolerance limits set according to the reference spectrum. Pre-test Pre-test level: 0.1~100% Starting speed: fast, slow Initial Drive: User Defined Initial Start Voltage Maximum drive limit: User defined maximum drive voltage for pre-test Test run plan Test Events: Magnitude and Dynamic Runtime Interrupt checking: off, on Control loop: open loop, closed loop Store results: screen bitmap, active pane, all panes, automatically store defined content Generate test reports: simple report, full report Pause experiment: set pause time Loop: set the start and end of the loop and the number of loops Run test sequence: switch and run multiple tests in sequence Safety Line interruption check: Automatically check the number of out-of-tolerance lines and compare with the allowable value, the line interruption rate is 0~1 Effective value limit: Check whether the effective value of the control exceeds the set maximum and minimum limit Manual abort: The user can stop the test by the "Stop" on the control panel and the "ABORT" button on the front panel of the control box Run: The fastest way is to press "ABORT" to interrupt the test run directly by hardware. Vibration table limit values: maximum acceleration, velocity, displacement. Pre-test: Use small-scale signals to check the system control loop and system performance, test the system transfer function, etc. Test: Continuous automatic open-loop detection, overload inspection, alarm, interruption tolerance band inspection, RMS interruption limit inspection, start, stop and change magnitude at the rate specified by the user, drive signal limit. Floating target spectrum: When the magnitude changes, the target spectrum, alarm, and interrupt tolerance follow the current magnitude change, and automatically check the number of out-of-tolerance lines in the current magnitude test Open-loop sensitivity: insensitive, normal, sensitive. Manual operation during the test Run open actions: stop or start a test, pause or resume a test Level adjustment: increase or decrease the level manually, or set the level directly Run jump: manually jump to the next event in the schedule Run control operation: valid or invalid for interrupt detection, control open-loop or closed-loop Display operation: add/delete cursor, add/delete window, change display content or interface, etc. Test report: generate WORD/PDF test report Peak/Valley Cursors: Automatic peak/valley detection and marking Ordinary cursor: single cursor, double cursor, read the X, Y of the position pointed by the cursor Harmonic cursors: mark harmonics Online status display Key parameters: current magnitude, peak value of driving voltage, target acceleration, velocity, displacement value and controlled acceleration RMS value Time: total running time, full scale time, current scale time, remaining time Current status: pause, pre-test, test run, alarm and test interruption, etc.

Sine Performance Index

The VCS sine control system performs effective sine frequency sweep and fixed frequency control by generating a 1Hz to 10000Hz continuous sweep sine wave. The drive signal produces a true analog sweep. The adaptive control algorithm based on the update of sinusoidal signal amplitude can quickly respond to system changes, and has high control precision and control dynamic range.

Control method Equalization method: transfer function Control loop: adaptive control based on sinusoidal signal amplitude update, which can quickly respond to changes in system nonlinearity, resonance vibration points and dynamic loads Control performance Dynamic range: 110dB Closed loop time: 10ms Drive signal: provides analog quality swept sine signal Waveform distortion: <0.3% Signal-to-noise ratio greater than 100 dB Frequency resolution: 0.01% Control parameters Control strategy: single channel control, weighted control, maximum value, minimum value Operation mode: manual, automatic Proportional filter bandwidth: proportional bandwidth, fixed bandwidth Displacement sensor - low pass filter: 0.1~18750Hz Time domain resolution: ≥10ms Starting rate: 1~120dB Linear sweep frequency: 0.01~6000Hz/min Logarithmic sweep frequency: 0.01~100 Oct/min, Frequency range: 1Hz~10000Hz Sweep parameters Frequency sweep mode: linear, logarithmic Sweep duration: frequency sweep times, time Sweep rate: The sweep rate can be set for each sweep event Initial direction: up, down Frequency setting: lower limit frequency, lower limit frequency, start frequency Resident parameters Frequency: set the frequency of dwell Duration: number of sweeps, time Target spectrum Resolution: maximum 4096 points Crossover point: defined by magnitude or slope, the number of crossover points is not limited Magnitude: acceleration, velocity, displacement Slope: constant acceleration, constant velocity, constant displacement Tolerance Spectrum: Define the alarm line and interrupt line in dB or % relative to the target spectrum Validity check: Automatically check the validity of the defined intersection points Peak calculation: automatically calculate the peak value of displacement, velocity and acceleration. Engineering Units: Imperial, Metric Display: Automatically display the reference spectrum with tolerance limits set according to the reference spectrum. Crossover point calculation: Automatically calculate the crossover frequency value of each segment. Acceleration type: logarithmic, dB Start test Starting speed: fast, slow Initial Drive: User Defined Initial Start Voltage Maximum Drive Limit: Rising maximum drive voltage for user defined tests Test run plan Test events: sweep, dwell, step Interrupt checking: off, on Control loop: open loop, closed loop Loop: set the start and end of the loop and the number of loops Pause experiment: set pause time Store results: screen bitmap, active pane, all panes, automatically store defined content Generate test reports: simple report, full report Run test sequence: switch and run multiple tests in sequence Manual operation during the test Run open actions: stop or start a test, pause or resume a test Level adjustment: increase or decrease the level by manual steps, and you can also set the level directly Frequency sweep control: change frequency, increase/decrease frequency, change sweep direction, manual frequency setting Sweep direction: change the sweep direction Run Jump: Manually transfer to the next event in the schedule, manually transfer to the next schedule Run control operation: valid or invalid for interrupt detection, control open-loop or closed-loop Display operation: add/delete cursor, add/delete window, change display content or interface report, etc. Test report: generate WORD/PDF test report Online status display Key parameters: current magnitude, peak value of driving voltage, target and controlled acceleration amplitude Time: total running time, full scale running time, current scale time, remaining time Current status: pause, pre-test, test run, alarm and test interruption, etc. safety Manual interruption: The user can stop the test run through the "Stop" button on the control panel and the "ABORT" button on the front panel of the control box. The fastest way is to press "ABORT" to directly interrupt the test run through hardware. Vibration table limit values: maximum acceleration, velocity, displacement. Test: Continuous automatic open-loop detection, overload inspection, alarm, interrupt tolerance band inspection, start, stop and change magnitude at the rate specified by the user, drive signal limit.

Resonant Vibration Search and Dwell (RSTD)

VCS Resonant Vibration Search and Dwell provides the functions of resonance search and dwell. The unique tracking algorithm of the system can quickly and accurately track the resonance vibration frequency. Harmonic vibration search and dwell includes all indexes of sinusoidal control, and also includes the following indexes. Resonance search Transfer function: any pair of input channels, or a test between an input channel and a control channel Search range: user-selectable start and stop frequencies within the frequency range defined by the reference spectrum Sweep rate: default scan rate, user-specified dedicated scan rate Detection criteria: resonance identification based on q value, transfer function amplitude, or both Reside Test mode: two modes: 1) stay while resonant search; 2) after completing the search, stay according to the stay list, this mode allows the user to modify the stay list Dwell mode: fixed frequency dwell, tracking dwell Fixed frequency dwell time: time, number of cycles; or amplitude drift rate Tracking residence criteria: reaching the specified time or number of cycles; resonance vibration frequency offset (frequency hz or percentage); resonance amplitude deviation rate (total offset or offset within a certain period of time) Test run plan Resonance search: define and execute resonance search events Resonant dwell: define and execute dwell events, corresponding to harmonic vibration search Search dwell: execute dwell immediately after searching for the resonance vibration point Signal display Search records: the same harmonic vibration search and dwell related operation records Dwell list: list all resident frequency points and corresponding amplitude, phase, q value, etc. Amplitude graph: transfer function amplitude vs. Frequency variation curve Phase diagram: the curve of transfer function phase versus frequency Safety Manual interruption: The user can stop the test run through the "Stop" button on the control panel and the "ABORT" button on the front panel of the control box. The fastest way is to press "ABORT" to directly interrupt the test run through hardware. Vibration table limit values: maximum acceleration, velocity, displacement. Test: Continuous automatic open-loop detection, overload inspection, alarm, interrupt tolerance band inspection, start, stop and change magnitude at the rate specified by the user, drive signal limit.

Typical Shock Control

The typical shock control provides the shock test function of the classic shock waveform, adopts the adaptive control algorithm based on the transfer function, can quickly respond to the nonlinearity of the system and the change of the dynamic load, and has strong system adaptability and high control precision.

Control method Equalization method: transfer function Control loop: adaptive control based on transfer function update, which can quickly respond to the nonlinearity of the system and the change of dynamic load Control performance Dynamic range: 90dB Pulse definition Pulse type: half sine, front peak sawtooth, back peak sawtooth, triangle, rectangle, trapezoid, haversine. Pulse duration: 0.5~3000ms Pulse amplitude: the user can input the pulse amplitude according to the needs Frequency range: 0~18750 Hz Unit: imperial, metric Pulse compensation Compensation method: front and rear pulse compensation, front pulse compensation, post pulse compensation Compensation waveform: half sine, rectangular, rectangular harmonic Pre-pulse amplitude: 1~100% After pulse amplitude: 1~100% Tolerance Type: MIL-STD810G, IEC60068227, GJB150A, ISO standard, user-defined interrupt control limit. Control parameters Operation mode: manual, automatic Control channel: single channel control, weighted control Pulse Interval: Defines the time interval between two pulses Average: 1~10 Pre-test Pre-test level: 0.1~100% Starting speed: fast, slow Initial Drive: User Defined Initial Start Voltage Maximum drive limit: User defined maximum drive voltage for pre-test Test Plan Run Test events: magnitude and number of pulses Interrupt checking: off, on Control loop: open loop, closed loop Store results: screen bitmap, active pane, all panes, automatically store defined content Generate test reports: simple report, full report Pause experiment: set pause time Loop: set the start and end of the loop and the number of loops Pulse polarity: forward, reverse Safety Open loop detection: automatic detection of control loop open loop Input signal: input channel open loop, overload check Line interruption check: Automatically check the number of out-of-tolerance lines and compare with the allowable value, the line interruption rate is 0~1 Tolerance: MIL-STD810 (US military standard), ISO standard, user-defined interrupt control limit. Interrupt button: interrupt test run directly via hardware Shaker Limits: Maximum Acceleration, Velocity, Displacement Drive signal limit: limit the peak value of the drive signal Open-loop sensitivity: insensitive, normal, sensitive. Manual operation during the test Run open actions: stop or start a test, pause or resume a test Magnitude adjustment: manually step to increase or decrease the magnitude, directly set the magnitude Run Jump: Manually adjust to the next event in the schedule Run control operation: valid or invalid for interrupt detection, control open-loop or closed-loop Display operation: add/delete cursor, add/delete window, change display content or interface report, etc. Test report: generate WORD/PDF test report Shock pulse: output shock pulse manually, change pulse polarity Online status display Key parameters: current magnitude, peak value of drive voltage, target and controlled acceleration peak value and RMS value Time: the number of output pulses, the number of remaining pulses, the number of current level pulses, the number of full level pulses Current status: pause, pre-test, test run, alarm and test interruption, etc. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Water Cooled Electromagnetic Vibration Testing Machine 2700Hz Electromagnetic Vibration Testing Machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Wire Damage Testing Device Terminal Mechanical Stress Tester for Electrical Connectors |

|

Random Vibration Test System Sine Sweep Electromagnetic Vibration Testing Machine |

|

Large Package Drop Test Machine Zero Height Carton Drop Tester For Packaging Testing |

|

Industrial Van Shower Test System Commercial Vehicle Rain Test Waterproof System |

|

IPX5 IPX6 Water Spray Test Chamber For Waterproof Testing Of Electronic Devices |

|

Electromagnetic Vibration Testing Machine Random Sinusoidal Vibration Test |